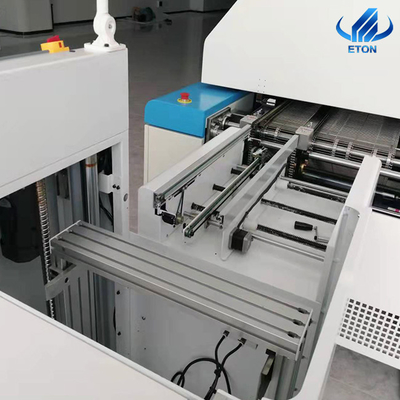

Easy operation 390MM collecting finished PCBA board SMT Un-loader

Machine main features

1. The device of unloading PCB in the SMT production line;

2. PLC control, color man-machine interface operation;

3. Adopting the structure of steeping motor to push the board, the force and speed of the pushing board can be adjusted;

4. Auxiliary positioning brake system, accurate positioning, fast rising and falling speed, high production efficiency;

5. Multiple electric distribution circuit protection, safe and reliable;

6. Acousto-optic alarm system, abnormal information text prompt, easy operation and maintenance.

7. Standard SMEMA signal communication mode.

| Description |

This equipment is used for the lowering operation of the circuit board in the production line |

| Number of turnover frame |

One box on working, two boxes out of frame segment, two boxes into the frame segment(or customer specified) |

| Send board time |

Around 6 s |

| Frame change time |

Around 25 s |

| PCB thickness |

0.4-0.3 mm |

| Transmission height |

900±20 mm |

| PCB size |

80*50-510*390 mm |

| Dimension |

2250*1010*1200 mm |

| Size of turnover frame |

535*460*570 mm |

| Approximate weight |

About 240 KG |

| Transmission direction |

Left-right, right-left |

| Air pressure and air flow |

4-6 Bar, up to 1L/min |

Machine application

Our advantage

- Focusing on SMT high speed pick and place machine more than 20 years

- The products exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc.

- ETON obtained 9 invention patents, 112 practical patents, 12 software copyrights of intellectual property technologies, to be a leading manufacturer of SMT trade.

Packages

As for the package of the machine, we put it in film packing and foam cotton, to prevent the dust and water of protecting the machine and keep dry of the machine during transportation, and equip with wooden boxes to transport to the specified port.

Service

Pre-sale service

Provide suitable production plan

Advise on plant electrical equipment and layout

Sale service

Report machine status in time

Follow up and send test machine video

After-sales service

Software lifetime upgrade

24 hours to deal with problems online

Engineers can arrive on site to teach operation and debug the machine

Regular visit (one year warranty period, spare parts repair free; Once or twice a year after warranty)

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!