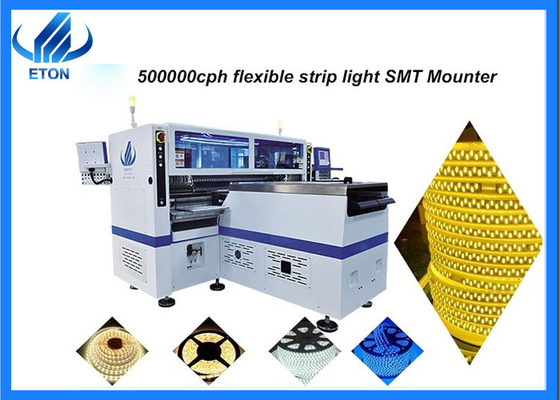

100m Led strip mounter 136 nozzles with 500K

Features

High Accuracy Magnetic Linear Motor + Panasonic Servo Motor

136 heads 136 feeder stations Four Arm four module , 34 nozzles for each mounting part. Part A or part B can be mounted separately or synchronously.

Vision alignment, Mark correction

Calibration automatically, high precision, available for RGB

Capacity can Reach 500 000 CPH

Parameter

| Dimension (L*W*H) |

3454*3035*1777 mm |

| Total weight |

3100kg |

| PCB Length width |

250mm*any length |

| PCB thickness |

0.1-0.5mm |

| PCB clamping |

Vacuum adsorption, cylinder splint, adjustable track width |

| No.of feeders station |

136 PCS |

| No.of head |

136 PCS |

| Mounting speed |

500000 CPH |

| Components |

LED3014/3020/3528/5050,Capacitance, resistance, bridge stack, etc |

| Operating environment |

9.6 KW |

LED Flexible Strip Production Process

| Step 1 |

Loader Machine |

Sending the FPCB roll to printer machine |

| Step 2 |

Semi-automatic Stencil Printer |

Printing the solder paste on the flexible PCB |

| Step 3 |

Buffer Stage |

Buffer and transport the flexible PCB to pick and place machine |

| Step 4 |

Pick and Place Machine |

Mounting LED chips and components on flexible PCB |

| Step 5 |

Transportation Belt Line |

Transport the flexible PCB to reflow oven |

| Step 6 |

Reflow Oven |

Heating the solder paste with FPCB to welding the components on FPCB |

| Step 7 |

Unloader Machine |

Rewinding the finished Flexible strip |

Our advantages

Rich experience in SMT Industry Line. ETON set up more than 10 years, we are leading manufacturer of SMT machine in China.

Our machines are of better quality, more accurate and faster to mount. We also have our own exclusive patented technology such as dual motor electronic Feeder feeding system, flight identification visual alignment, group picking and group placing and so on.

Package and transport

we use the vacuum packaging and wooden box packaging.

First, Wrap the machine in foam cotton and stretch film to protect the outside of the machine

Second, Vacuum packaging, put the desiccant into a vacuum bag to prevent moisture, and use straps to fix the machine;

Third,professional wooden box packaging.

Customer's factory

1. LED bulb factory

2. LED display factory

3. LED Tube factory

4. LED Strip light factory

etc......

FAQ

Q: Why we choose your company?

A: ETON is the No. 1 brand of placement machines in China, enjoys a high reputation at home and abroad, has extensive influence, and is a leader in China's placement machine industry.

Q: This is the first time I use this kind of machine, is it easy to operate?

A: It is easy to operate, the language of the machine is English, and we will teach you the basic operation. If you still have any questions, please contact us by e-mail, wechat, phone, Skype,Whatsapp or other contact information.

Q: How can you make sure that the products won’t be damaged or wet?

A: We take multiple measures to protect the products. They are first packing with individual. We put them into a carton and wrapped with plastic film and sealed with tape tokeep the cartons in position and protect them from water.

Contact me

David whatsapp/wechat/Tel: +86 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!