R&D software double gantry SMT multi-functional placement machine

Description

Machine main features

- Single module X,Y,Z axis high-end magnetic linear motor, high precision than classic model

- Y axis double drive gantry, higher speed more stability

- The placement head adopt independent vacuum detection, improve the placement performance

- Off-line programming, save time of changeover cycle

- Equipped coordinate import function, more intelligent

Machine main parameter

| Model |

KT10S |

| Dimension |

| Length |

1490mm |

| Width |

2020mm |

| Height |

1650mm |

| Total Weight |

2080kg |

| PCB |

| PCB Length Width |

Max:500*450mm(1200*450 option) Min:50*50mm |

| PCB Thickness |

0.5-5mm |

| PCB Clamping |

Cylinder clamping, track width adjustable |

| Mounting Mode |

Group picking and separate placingseparate picking and separate placing |

| O.S. |

| System |

Windows7 |

| Software |

R&D independently |

| Display |

Touch screen monitor |

| Input Device |

Keyboard, Mouse |

| Vision System |

| No. of Camera |

1 PCS (Head flight vision camera) |

| 1PCS Mark camera |

| Mounting Precision |

CHIP±0.03mm QFP±0.025mm Cpk ≧1.0 (3σ) |

| Mounting Height |

≦16mm |

| Mounting Speed |

48000 CPH(Under best condition) |

| Components |

LED , capacitors, resistors, shaped components, etc. |

| Components Speed |

0.2mm |

| No. of Feeders Station |

52 PCS (104 PCS customize, IC tray/nozzle change option) |

| No. of nozzles |

10 PCS |

| Power |

220AC 50HZ |

| Power Consumption |

1.5kw |

| Operating Environment |

23℃±3℃ |

| Transmission Speed |

>1000mm/sec |

| Transmission Direction |

Single(left→ right or right→ left) |

| Transmission Mode |

Online drive |

| Position Mode |

Optical |

| Gas consumption |

0.4-0.6mpa (4-6kgf/cm2)600N/min |

| Electrical control |

Independent research and development by ETON |

| Motion control card module 1 set |

Independent research and development by ETON |

| X,Y,Z Axis Drive way |

High-end magnetic linear motor |

| Feeding way |

Intelligent feeder with double motor |

| Production management MES system interface |

Customized |

Machine application

Our Exhibitions

Domestic exhibitions: Guangzhou Guangya Exhibition, Shanghai Munich Exhibition, Chongqing LED Light Exhibition, etc.

Foreign exhibitions: India Mumbai Exhibition, India Delhi Exhibition, Egypt Exhibition, Turkey Exhibition, Pakistan Exhibition, Thailand Exhibition, etc.

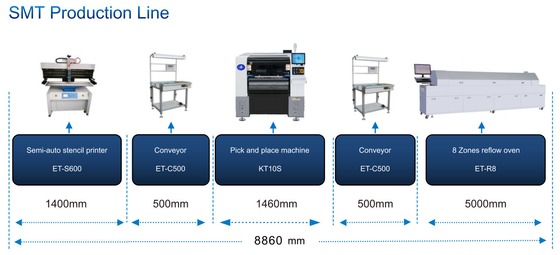

SMT Line solution

The equipment required for the semi-automatic production line includes:

- Semi-automatic printing machine: the solder paste is printed on the PCB pad through the stencil;

- Pick and place machine: mount the led chips or other components on the designated position on the PCB board;

- Reflow oven: melting the solder paste to make it adhere to the mounting components;

- Conveyor: inspect the placement and soldering quality, and also play a role in transferring PCB boards and buffering on the SMT production line

Certificates

As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 14 invention patents, 135 practical patents, 44 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA,etc.

Packages

Keep a good quality of the machine when during transportation till the destination of our clients which is an imperative aspect for one of a suitable service for our clients to buy our machine, so making sure of a qualified and sturdy packing is a key mission for us, here are the specified steps for your reference:

FAQ

Q.What kind of machine you have?

A.We are the high speed SMT pick and place machine manufacturer, and also we build our brand to more efficient and convenient machine for our customers. We have multifunctional type, honor series, value series with high precision and high productivity.

Q. Does your machines have quality certificates?

A. We are high-tech enterprise with CE, SIRA, CCC , ISO awarded as "Well-know brand" and many technology patents, and have rich experience (more than 11 years) in LED light production line program.

Q. Is the machine easy to operate?

A. Yes, our machine is very intelligent and easy to operate, like the intelligent phone, also the software is made by our company, so we know how to make it more intelligent and operate friendly.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!