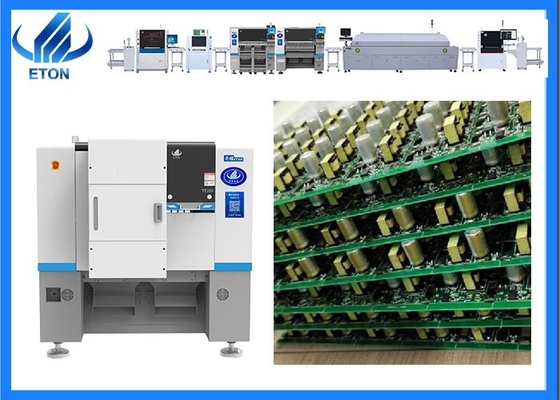

YT10S SMT PICK AND PLACE MACHINE:

10 HEADS,52 FEEDER STATIONS.

Apply to 0402~35*35mm components need to option fixed camera

PCB size:500*450mm,50*50mm

Application:power driver,household electric board,led light,downlight,streetlight,panel light,3c products,etc

NEW Functions and performence:

1. Integrated Placement Head

The 10 sets of Z axes are independently controlled by modular Magnetic Linear motor,Which greatly improves The Speed ,accuracy and stability

2.Precision Corner System

The modular corner system independently controls the angle of each component to ensure high-precision placement. 10 suction nozzles per head, with a center distance of 16mm.

3.Head Flight Vision recognition Camera

Head flight recognition + fixed flight recognition camera (option), high speed and high-precision identification.the component can do 0201 to 35*35mm, height 16mm, other height can be customized

Thechnical Parameter of smt chip mounter

| Model |

YT10S |

| Dimension |

| Length |

1480mm |

| Width |

2020mm |

| Height |

1650mm |

| Total Weight |

2380kg |

| PCB |

| PCB Length Width |

Max:500*450mm(1200*450 option) Min:50*50mm |

| PCB Thickness |

0.5-5mm |

| PCB Clamping |

Cylinder clamping, track width adjustable |

| Mounting Mode |

Group picking and separate placingseparate picking and separate placing |

| O.S. |

| System |

Windows7 |

| Software |

R&D independently |

| Display |

LED monitor |

| Input Device |

Keyboard, Mouse |

| Vision System |

| No. of Camera |

1 PCS (Head flight vision camera) |

| 2 PCS Mark camera |

| Mounting Precision |

CHIP±0.03mm QFP±0.025mm Cpk ≧1.0 (3σ) |

| Mounting Height |

≦16mm(Other height can be customized) |

| Mounting Speed |

48000 CPH(Under best condition) |

| Components |

0201~15MM packaging material and IC material(Optional fixed camera for 0201~35*35MM), Other component size can be customized |

| Components Speed |

0.2mm |

| No. of Feeders Station |

52 PCS (104 PCS option) |

| No. of nozzles |

10 PCS |

| Power |

220AC 50HZ |

| Power Consumption |

1.5kw |

| Operating Environment |

23℃±3℃ |

| Transmission Speed |

>1000mm/sec |

| Transmission Direction |

Single(left→ right or right→ left) |

| Transmission Mode |

Online drive |

| Position Mode |

Optical |

| Gas consumption |

0.4-0.6mpa (4-6kgf/cm2)600N/min |

| Electrical control |

Independent research and development by ETON |

| Motion control card module 1 set |

Independent research and development by ETON |

| X,Y,Z Axis Drive way |

High-end magnetic linear motor |

| Feeding way |

Intelligent feeder with double motor |

| Production management MES system interface |

Customized |

smt chip mounter Application :SMT Line

Semi-automatic Stencil Printer:Solder paste Printing

| Model |

ET-S600 |

| Dimensions |

1400*800*1680mm |

| Platform size |

300×600mm |

| PCB size |

250×550mm |

| Template size |

550×830mm |

| Printing speed |

0-8000mm/min |

| PCB thickness |

0-50mm |

| PCB fine tuning range |

Front/side±10mm |

| Power supply |

1PAC 220V 50/60HZ |

| Platform height |

850±20mm |

| Repeatability precision |

±0.01mm |

| Positioning mode |

Outside/Reference hole |

| Weight |

Approx.200Kg |

Single-Rail Conveyor:

Operate the stencil printer to print the solder paste onto the PCB

| Model |

ET-C500 |

| Steel frame structure, rail length |

L=500 |

| Width adjustment range |

50~350 mm |

| PCB size |

500*350 mm |

| Transmission height |

920±20 |

| Transmission |

5MM flat belt conveyor |

| Speed |

Adjustable from 0.5 to 9 m/min |

| Motor |

One set of 25 W stepper motor |

| Control |

Industrial control panel |

| Transmission Direction |

Single (left → right ) |

| One section of control, two Sensors |

Pick And Place Machine:Mounting Part

The PCB board that has been brushed with solder paste will be sent to the pick and place machine for automatic mounting, and the pick and place machine will automatically pick components and place on PCB

8 Zone Reflow Oven:Reflow Soldering

The PCB board be mounted with components is sent to reflow oven,reflow oven will heat and welding the components with solder paste on PCB.

| Product model |

ET-R8 |

| Heating system |

NO. of heating zone |

Upper 8 hot air heating, lower 8 hot air heating |

| |

Length of heating zone |

3000mm |

| |

heating method |

Full hot air |

| Delivery system |

PCB maximum width |

450mm mesh belt, no lead rail |

| |

Transport direction |

left-right,right to left(option) |

| |

Conveyor belt height |

Mesh belt 880±20mm |

| |

Delivery method |

Mesh belt drive + rail (optional) |

| |

Conveyor speed |

0-2000mm/min |

|

Control System

|

power |

380V 50/60Hz Three-phase five-wire AC:380V 50Hz |

| |

Starting power |

28KW |

| |

Working power |

7KW |

| |

Heating time |

Around 15 mins |

| |

Temperature control range |

Room temperature~350℃ |

| |

Temperature control method |

PID control + SSR drive |

| |

Temperature control accuracy |

±1℃ |

| |

Abnormal alarm |

Abnormal temperature alarm |

|

Machine system

|

Machine dimensions(L*W*H) |

4600mm*1000mm*1400mm |

| |

Machine weight |

1300kg |

Service ETON

- Professional solutions: Provide professional SMT Full line solutions

- Free Warranty: One-year warranty factory service. All parts damaged within the warranty period shall be replaced free of charge

- Free Installation: On-site free installation to ensure smooth production.

- Free Technical Training: Professional training of operating and maintenance.

- Free Technical Support: 7 * 24 technical online support.

- Free Software Upgrade: Offer free software upgrade whole lifetime

Contact Me

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!