SMT pick and place machine,LED light making machine,LED light production machine.

1, Mount: Mount 0402 to big component all specifications of SMD LED components. In addition to all the planar LED plane, other electronic components (such as resistors, capacitors) and high power LED and the lens can be produced.

2, Precise positioning: positioning block is the most convenient way to position the substrate, the origin of counterpoint, accurate positioning (repeat accuracy is 0.02mm). Mount angle range of 0-360 degrees, the accuracy of 0.1 degrees. Each suction nozzle is independent of angle, and one flight recognition camera, in addition to LED lamp can mount the traditional., bulb lamp, lamp, lamp, ceiling lamp, guardrail tube, LED drive power, copper lamp series and so on can be freely mounted.

3, high precision: X, Y, W axis are equipped with precision ball screw and guide rail, Z axis 8 sets of imported motor drive, enhance the smooth coordination of equipment movement, reduce abnormal noise, greatly improve the accuracy and speed of the patch.

2. FRQ

1) If machine have any problem after I receive it, how can I do ?

Free parts send to you for machine in warranty period.

.

2) MOQ ?

1 set machine, mixed order is also welcomed.

3) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Delivery your machine needed by air or by sea.

3 . Technical Parameter :

| Specifications |

ETON SMT Pick and Place Machine HT-E6T-1200 |

| Alignment |

Flying Vision |

| Number of Spindles |

8 heads |

| Placement Speed |

35,000 CPH(Optimum) |

| Placement Accuracy |

±50μm+3σ (Based on the Standard Chips) |

| Component Range |

Chip 0402 ~30mm |

| Board Dimension(mm) |

50(L) x 50(W)~500(L) x350(W) |

| Feeder Capacity |

8mm,12mm,16mm,24mm option,according to client products |

| Power |

AC 220 50/60Hz,single Phase |

| Air Consumption |

0.5 ~ 0.6MPa(5 ~ 6kgf/cm2) |

| Mass |

Approx. 1200kg |

| External Dimension(mm) |

2550(L) x 1650(D) x 1600(H) |

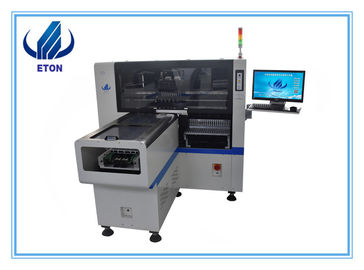

4 . Product Image :

5 .Company Information

ETON has launched its new Middle-speed SMT Pick and Place Machine, Equipped with a newly developed parallel 8 nozzle head, the ETON SMT Pick and Place Machine is capable of mounting a wide variety of parts and improving the mounting speed by up to 20~30%. The ETON Pick and Place Machine is robotic assembly machine for mounting electronic components on a " PCB" in the printed board mounting process. In addition to increasing the number of components mounted per cycle, ETON Pick and Place Machine also includes a new mechanism to improve the mounting speed by automatically changing the recognition sensor height.

6 .Packaging & Shipping

1)Standard wooden case package with vacuum package

2)Strong wood package for heavy and large equipment

7 .Our Services

Excellent Service .

Upgrade the software will be free for whole lifetime of machine .

Visit customer regularly and gather information .

Pre-Sales Service

* Inquiry and consulting support.

* Sample machine testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!