480mm Mesh Width SMT Mounting Machine ET-R8 With Guide Line Hot Air Oven

Characteristics

Reflow soldering has the following characteristics compared to wave soldering:

1. Reflow soldering only applies solder to the required parts, which greatly saves the use of solder

2. When the component placement position is deviated, due to the surface tension of the molten solder, as long as the solder is placed in the correct position, the reflow can automatically correct this small deviation during welding to fix the component in the correct position

3. the solder will not mix into the object, the solder composition can be used to properly maintain the composition of the solder

Parameter:

1.4900mm length, 1270mm width, 1450mm height

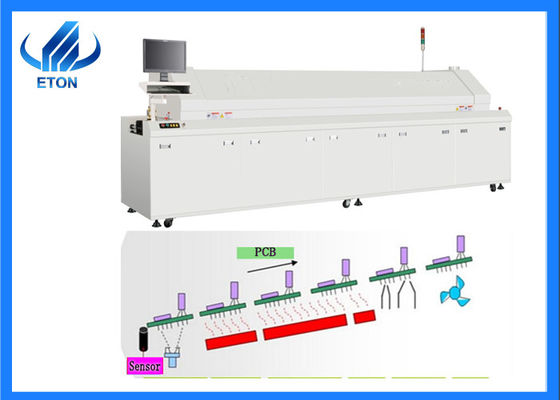

2. Up 8 heating Zones, down 8 heating zones, 2 cooling zone

3. Heat up time no more than 25 min

4. 0-1.8M/MIN mesh speed and 480mm mesh width

5. Apply solder paste type:Lead-free solder/Ordinary solder

6. Applicable components type: BGA,CSP etc. single/double sided

Features:

1. Each temperature zone using forced circulation, independent PID control, upper and lower independent heating, the temperature of the furnace chamber accurate, uniform, large heat capacity.

2. Due to the unique way to transport wind, surrounded by the return air patented design that eliminates the effects of the rail on PCB board to undesirable temperature, on PCB board of heating, it is more evenly and quickly than similar models.

3. Unique furnaces are the wind structure within different areas of the furnace can be different wind speed difference arising due to structure adjustment, heat uniform.

Packing:

In order not to cause the machine to collide during handling, our machine packing adopt vacuum add wooden box packing. It is very firm.

Also our can accept shipping or training , even flying, it is according to the customer needs. In generally, the machine will be delivery in four weeks after payment.

Company Information:

ETON history:

In 2007, set up the R&D center in Taipai, began to LED special purpose SMT machine technology and patent research and development.

In 2011, set up Shenzhen Eton Automation Equipment Co., Ltd. Meantime, HT-12 began selling.

Until now in 2011 to 2018, ETON have research and development more than 15 modules and a lot of honorary certificates

ETON mission:

To create a national brand, build international Chinese enterprise.

Effect of reflow soldering rail transport speed on welding quality

For PCB boards, too fast or too slow rail transport speeds can cause SMT components to experience too long or too short heating times, causing flux volatilization and solder joint tinting changes beyond the allowable SMT components. The rate of temperature rise will also cause some damage to the component. Therefore, in terms of the transportation speed of reflow soldering, we are adjusting the appropriate transportation speed under the premise of meeting the standard reflow profile and satisfying the production requirements of the customer as much as possible.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!