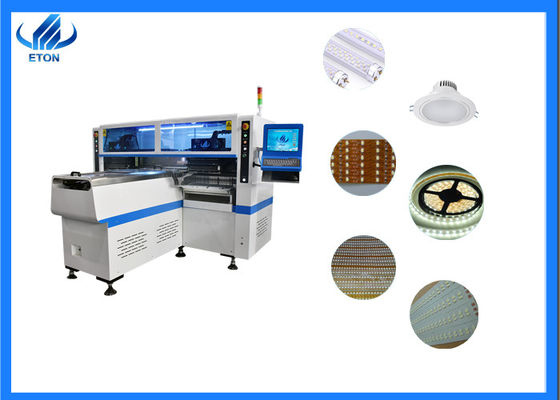

flexible strip light rope light pick and place robot smd mounting machine price

HT-F9 professional high speed mounter apply to the 0.6m,0.9m,1.2m rigid PCB and 0.5m,1m LED flexible strip. Mounting components includes LED 3014/3020/3528/5050 and resistors,capacitors,bridge rectifiers.

HT-F9 professional high speed mounter can producing with 2~4 types of materials with high capacity,available for board with any proportion of LED chip and resistors.

Two mounting modules ,18 nozzles for each mounting part, part A or B can be mounted separately or synchronously.

Exclusive patent technology :group to take and group to mount .

Application:

Apply to the 0.6m,0.9m,1.2m rigid PCB and 0.5m,1m led flexible strip,Producing with producing 4 types materials at the same time with high capacity ,available for board with any proportion of led chip and resistor.

Performance introduction

High precision

With a new visual recognition system, five imported cameras, visual alignment, Mark correction technology, combined with optical positioning method, accurately identify the position of PCB board and quickly and accurately mount components.

Attached its technical parameter:

| HT-F9 |

| PCB |

PCB length width |

Max:1200*330mm min:80*330mm |

| PCB thickness |

0.5~5mm |

| O.S. |

system |

Windows 7 |

| software |

R&D independently |

|

Vision

system

|

No.of camera |

5 sets of imported camera

Vision alignment,mark correction

|

| Mounting precision |

0.02mm(repeat precision) |

| Mounting height |

<15mm |

| Mounting speed |

200000CPH |

| Components |

LED 3014/3020/3528/5050 and resistors,capacitors ,bridge rectifiers. |

| Components space |

0.2mm |

| No.of feeders station |

68PCS |

| No.of nozzles |

68PCS |

| Power |

380AC 50HZ |

| Power consumption |

6KW |

| Transmission direction |

Single (left to right or right or left) |

| Transmission mode |

Auto online drive |

| Electrical control |

Independent research and development by ETON |

| Motion control card module 1set |

Independent research and development by ETON |

| X,Y,X axis drive way |

Servo motor +magnetic linear motor |

The production layout

Wooden vacuum packaging:

Our close-up style:

Remarks:

1.Payment terms: Deposit 30% in advance,the balance 70% should be paid before shipment by T/T.

2.Delivery time: 30 days after deposit.

3.Warranty: 1 year.(including spare parts)

After sales service

Maintenance period: 1 year.

Visit customers regularly and gather information.

Provide latent information about technology and equipment.

FAQ

Q:How is the training?

A:After you buy the machine, we will have an engineer to your factory for free installation and training

Q:Is it hard to use these machines?

A:No,not hard at all.For our previous clients,at most 3~5 days is enough to learn to operate the machines.

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes,In Both Chinese and English.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!