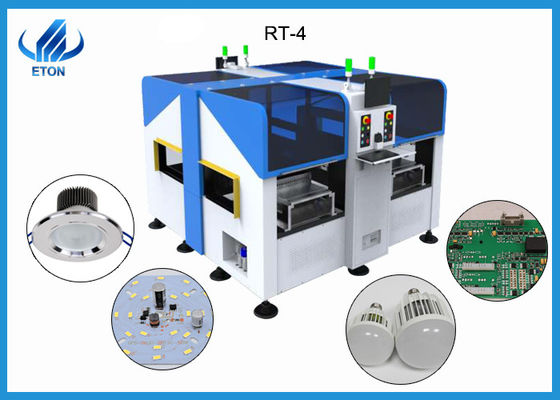

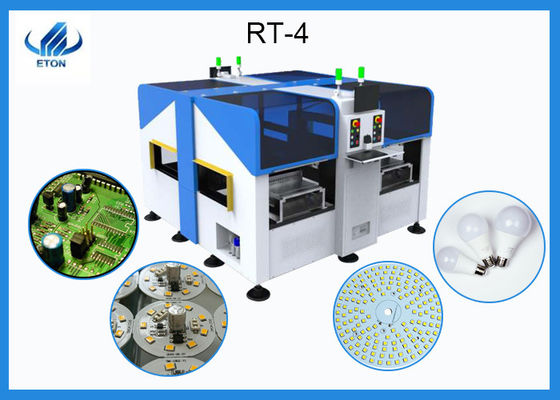

Four-module high capacity save space 120000CPH Led bulb manufacturing machine line chip mounter

Features:

1. The four-module magnetic linear multifunctional placement machine adopts high-end magnetic linear motor + servo motor, which greatly improves the accuracy and stability of machine placement.

2. The four modules can produce four different products at the same time, which greatly saves manpower, material resources and production time, improves the efficiency of placement, and the production capacity reaches 120,000 to 140,000 CPH.

3. It has 80 feeders and 40 suction nozzles.

4. 8 sets of high-speed synchronous recognition cameras, which can simultaneously perform visual correction for 40 placement heads to absorb different components, with automatic replenishment function.

5. Two modules on the same side can be mounted with two different materials, such as the first module mounting lamp beads, the second module mounting various special-shaped components, etc., which can save PCB board mounting time. Improve work efficiency.

6. The XY axis movement mechanism adopts high-compact grinding ball screw + servo motor, which has high precision, long life and low wear.

7. Intelligent automation programming: The operation is simple and convenient, which greatly saves the events of editing process files and improves work efficiency.

Company after-sales service

Technical parameter:

Dimension:2086*2237*1500mm

Total Weight: 4500kg

PCB Length Width:MAX:500*310mm MIN:50*50mm

PCB Thickness:0.1~6mm

PCB Clamping:Electric Clamping

Mounting height:≤7.5mm

No. of Camera:8PCS

Mounting Precision:±0.04mm

Mounting Speed:120000~140000CPH

Components Space:0.2mm

Feeders Station:80PCS

No. of nozzles:40PCS

Components:LED,capacitor,resistor,shaped components,etc. MAX:17mm, MIN:0402)

X,Y,Z Axis Drive way:Magnetic linear motor + servo motor

Feeding way:Electric feeder with double motor

Motion control card module 1 set: Independent research and development by ETON

Application:

1.Mounting components:LED, capacitors, resistors, IC, Shaped components, etc.

2.Mounting products: DOB, bulb light, down light, panel light, street light, power supply, circuit board, driver, home appliance control board, etc.

ETON Compony:

Shenzhen ETON Automation Equipment Co., Ltd. is a high-tech enterprise with the concept of building a national brand, providing "professional, efficient, and low-consumption" products, focusing on R&D, production and sales of LED automatic high-speed energy-saving placement machines.

With the development trend of global greening and energy saving, as well as the rapid development of the LED industry and the requirements for production technology, ETON and the United States, Taiwan, Hong Kong and many technical personnel, after four years of joint research, successfully developed a global fast, stable, The complete ETON LED automatic high-speed energy-saving placement machine series products, with its unique technology, strong production capacity advantages, and perfect after-sales service system, have completely subverted the LED placement machine industry field and solved the problem of long light boards and long light strips. Low production capacity, high labor costs and other problems, and has obtained a number of patent certificates and support.

In terms of production capacity, ETON's products are currently the world's fastest placement machine. The actual production capacity of the "ET" and "HT" series of LED placement machines has reached 250,000 CPH. Products can be customized according to customer requirements, and the five-meter light strip can also reach 200,000CPH. Some listed companies including Changfang, Wanrun Technology, Mulinsen,, Century Classic, Zhuhai Taobo, Huizhou International Exhibition Electronics, etc. have become our customers.

The "speed" and "stability" of products are the capital that ETON is proud of. ETON's manufacturing plan, the pursuit of rigorous quality management and perfect after-sales service, provide customers with professional production lines and provide technical support. These advantages and services have enabled the company to rapidly develop into a global manufacturer with strong R&D and manufacturing strength and influence in the field of LED automation equipment.

Our Client:

We have exported machines to more than 20 different countries, such as India, Egypt, South Korea, Turkey, Brazil, etc.

Our domestic customers include NVC, TCL, HELI, FSL, ETI, KONKA, OPPLE, MLS, etc.

In India, such as RK, skyquad, SURYA, Fiem, Calcom, POLYCRB, are our customers.

After service:

There are offices in Delhi and Mumbai, India, and can arrange for local engineers to install machines for you for free.

In addition to India, we also have local engineers in Turkey and Egypt who can install machines for you for free.

The warranty period is one year. During the warranty period, parts can be replaced free of charge

Free installation and training.

Provide free software updates.

Regularly visit customers to understand usage and collect customer opinions.

Provide customers with the latest production technology and equipment information on a regular basis.

About transaction information

Logistics transportation: We support three modes of transportation by sea, land and air.

Standard packaging: vacuum packaging + wooden box packaging, double protection

Supply Ability: 50 units per month

Payment method: T / T

Delivery time: 30 days after deposit

Minimum order quantity: 1 set

FAQ:

1.Do you have any customers in India? How many machines are there in India?

A: Yes, We have many big clients in India, Such as RK,SURYA,Fiem,Calcom,POLYCRB, etc. We have sold over a hundred machines to India and we go to the exhibition every year.

2. Does your machine have a quality guarantee?

The selling point of our machine is good quality. We can guarantee the quality of the ETON pick and place machine. Our company's quality policy is quality first and customer orientation.

3. Can you support whole SMT line?

A: Yes, we can provide whole line solution if you want. We are very professional on SMT field.

4.How is your company?

Our company ETON is the largest manufacturer of highspeed pick and place machine.

We start from 2011,around 10 years. we have around 50000 square meter industrial manufacturing park and around 300 person in company.

In the market ,around 80% of large LED factory are our client.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!