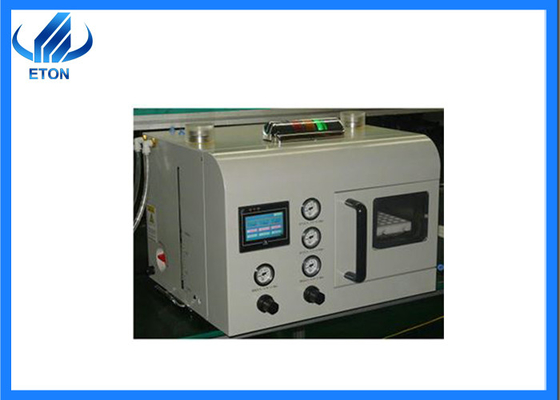

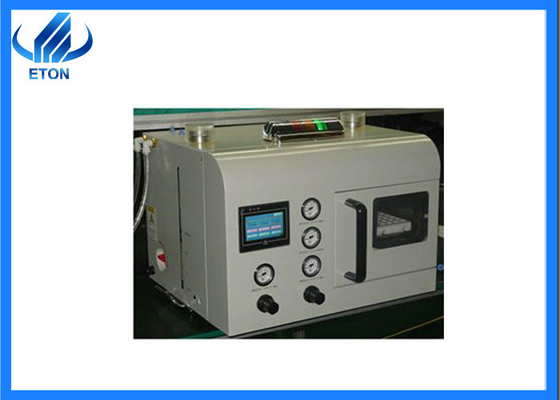

Vacuum Smt Nozzle Cleaning Machine Used In SMT Production Line

High-quality vacuum nozzle cleaning machine used in SMT production line

Description

Principle:

The suction nozzle cleaning machine adopts a unique mechanical design. It uses fluid mechanics to break the water and produce a very small high-pressure water mist.

It forms a powerful kinetic energy jet on the suction nozzle at the sonic speed (v = 360m / s), forms a continuous energy field above the suction nozzle to be cleaned, and thoroughly smashes the dirt on the surface and inside (since the suction nozzle is placed independently, it will not damage the suction nozzle during the cleaning process). After cleaning, it will not damage the suction nozzle During the process, the cleaning solution (deionized water or distilled water) is automatically discharged directly.

Structure:

- Machinery: imported 304 stainless steel is used for key parts of the whole machine, and imported 316 stainless steel is used for special parts to ensure that the whole machine will not rust due to the use of water, thus affecting the service life of the equipment and other safety hazards;

- Pneumatic: using imported SMC pneumatic components to better ensure stable and efficient work efficiency;

- Control: the machine adopts high-quality touch screen human-machine interface and PLC control.

Technical parameter

| pressure |

pressure |

compressed air |

| Intake pressure setting |

0.5~0.55MPa |

| Injection pressure setting |

0.35~0.38MPa |

| Nozzle injection pressure |

≤0.4MPa |

| Tube |

Intake manifold |

¢12tube |

| Drain tank water pipe |

¢8tube |

| Cleaning liquid |

Cleaning liquid |

Industrial deionized water |

| Liquid consumption |

≤300cc/h(5cc/min) |

| Capacity of water storage tank |

1200cc |

| Power Supply |

Power Supply |

AC220~240V |

| Plug |

3-Pin |

| Consumption of electricity |

≤0.1Kw |

| Environment |

Working environment temperature |

-5℃~ (But not frozen.) |

| Liquid temperature |

0℃~ (But not frozen.) |

| Working environment humidity |

10~60%RH |

| Environmental humidity of equipment |

10~60%RH |

| dust |

0.1mg/m³(No conductive dust) |

| Corrosive gas |

Not allow |

| Others |

Outline size |

655(L) x 560(W) x 475(H) |

| Weight |

(Including cleaning fluid 2000cc) |

Features

High quality touch screen human-machine interface, PLC control;

The pneumatic part uses imported SMC pneumatic components from Japan, which ensures stable and efficient working efficiency;

The key parts of the whole machine are all made of 304 stainless steel imported from Japan, and the special parts are made of 316 stainless steel imported from Japan, so as to ensure that the whole machine will not rust due to the use of water, thus affecting the service life of the equipment and other safety hazards.

Application

For the development of the electronics manufacturing industry, with the miniaturization of components, smaller equipment spacing, and lead-free effects, the accuracy of the patch is getting higher and higher. If the nozzle is not clean, it will affect the patch’s performance on the most important factors. Precision and performance, so companies that develop in the electronics manufacturing industry, especially need nozzle cleaning machines.

Comparison chart

FAQ

- Do you have any service offices overseas?

We have service office in India, and have India engineer in Delhi and Mumbai, can support you.

- What do you do if something goes wrong with my machine?

First of all, we will let the engineer contact you online to solve, if the line can not solve, we will arrange for the engineer to your factory to solve.

- Is your software interface in English?

English interface and Chinese interface are both available.

- How is the training?

After purchasing our machine, first we will send you the installation and operation video, and then we will arrange engineers to go to your factory for installation and training, or you can arrange your engineers to study and operate in our factory.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!