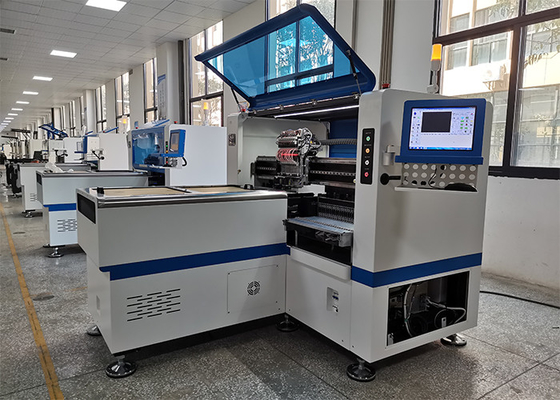

Electric feeder mark camera 45000CPH LED lens pick and place machine

Product description

| 1. While producing a variety of PCBA, it can also mount lenses, IC and various special-shaped components.The minimum mounting components range is 0402, the maximum mounting components range is 15mm, and the maximum width span of the components is 17mm,The production capacity can reach 45000 CPH (our best conditions). |

|

2. The maximum length of guide rail transmission is 1200mm, which means that this model can be pasted with different products, ranging from 100 * 100 bulb PCB board to 1200 * 500mm LED tube PCB board.

|

|

3. The single-mode group has 12 suction nozzles and 28 feeders, each head is controlled by a servo motor, The two work together. PCB boards with different angles can be mounted, such as the circular state of bulbs

|

|

4. Exclusive patented technology

Electronic feeder feeding system

Vision alignment flight identification, mark correction

Non-stop material re-loading function

|

Feature

1. The x-axis enters and exits the PCB board and is pasted while entering and leaving. It adopts linear motor, servo motor and stepping motor, which has higher precision and longer service life.

2. Mark camera identification, scan the reference point of PCB board to prepare for the preparation of mounting program, and flight identification camera identifies whether there is material leakage, so as to ensure the high accuracy of mounting.

Parameter

| PCB size |

Max:1200*500mm Min: 100*100mm |

| PCB thickness |

0.5-5mm |

| PCB clamping |

Adjustable pressure pneumatic |

| Mounting mode |

Separate to pick and separate to stick |

| Mounting height |

<15mm |

| Mounting precision |

±0.04mm |

| Mounting speed |

45000CPH |

| Components space |

0.2mm |

Appliance

HT-E8S model can be made of various products, such as bulb, panel lamp, street lamp, lamp tube, display screen, IC, etc. as long as it meets the length of its PCB board, everything can be met within 1.2m. Of course, there are also models that can be customized, and the length of PCB board can reach 1.5m.

What elements constitute the SMT chip processing process?

1. Solder paste printing: solder paste is missed on PCB pad through steel mesh to prepare for the welding of components. The equipment required in this process is solder paste printing machine, which is divided into full-automatic and semi-automatic.

2. Mounting. To accurately install the surface assembly parts to the fixed position of PCB, the equipment required in this step is the mounter. The product is located behind the SMT patch production line.

3. Reflow welding. The effect is to melt the solder paste so that the components on its surface can be bonded with the PCB board. The required reflow oven is located behind the mounter. Step 4 is to clean the SMT patch. Firstly, the welding slag harmful to human body on the assembled welding board needs to be cleaned. The cleaning machine used is this kind of equipment, and the position can not be fixed.

FAQ

Q1: What is the application scope of your product?

A:Our products have great advantages in the production of LED lamp drivers and light source. If you are an LED lamp manufacturer or are transferred to this industry, we can provide you with more information.

Q2:Have you obtained any certificates for your products?

A:Yes,Our machine has won many certificates, such as CCC, CE, Sira, and our enterprise has won the national high-tech award because of its strong R & D strength.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!