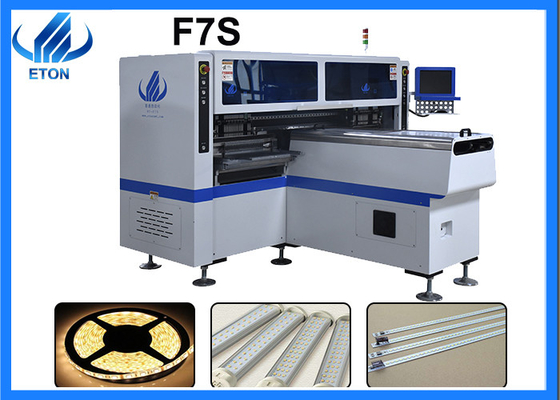

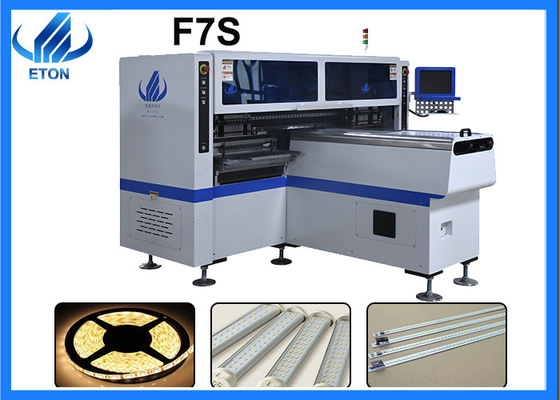

R&D independently mounter 2700 mm for 1.2m linear tube pick and place machine

Description

High speed mounter HT-F7S apply to various components as led 3014/3020/3528/5050, and resistors, capacitors, bridge rectifiers, etc, for the products, it apply to 0.6m, 0.9m, 1.2m rigid PCB and 0.5m, 1m led flexible strip, furthermore, it can produce 2-4 types of materials at the same time with high capacity.

Machine main features

- Apply to the 0.6m, 0.9m, 1.2m rigid PCB and 0.5m, 1m LED flexible strip, producing with 4 types materials at the same time with high capacity, available for board with any proportion of LED chip and resistor.

- Calibration automatically, high precision, available for RGB.

- Exclusive patent technology: Group picking and group mount placing.

- IPC9850 capacity: 200000-250000 CPH

Machine parameter

| Model |

HT-F7S |

| PCB length width |

Max: 1200*330mm

Min: 100*100mm

|

| PCB thickness |

0.5-5mm |

| PCB clamping |

Adjustable pressure pneumatic |

| Mounting mode |

Group picking and group placing |

| Mounting precision |

±0.02mm |

| Mounting speed |

150000-180000 CPH |

| No. of feeders station |

68 PCS |

| No. of head |

34PCS |

SMT Line solution

A whole semi automatic line which needs several devices for a whole semi production, as semi auto stencil printer machine, conveyor, pick and place machine and reflow oven etc.

The blowing is the function of each machine:

1.Semi auto stencil printer is aim of leaking solder paste or patching adhesive onto the solder pad of PCB to prepare for the welding of components; 2.Conveyor is used for the connection between SMT production lines, as well as buffering, testing, testing PCB boards or manual plug-in of electronic components;

3.Pick and place machine is to mount light beads or other surface mounted components at the designated position of PCB board;

4.Reflow oven is to melt the solder paste to fix and bond the components and PCB board.

Certificates

Shipping and Delivery

As delivery of the goods here are the three aspect for the transportation way:

FAQ

Q1. Can you arrange your engineers to our country for a training of the machine?

A1. Yes, our clients enjoy a free training for the machine as installation, maintenance etc.

Q2. How long is the machine maintenance period, whether it is free?

A2. The maintenance period of our machine is 1 year and its free for our clients.

Q3.How can I get an optimal line for our product?

A3. As the needs of the whole line solution, we will provide our professional suggestion and a whole line production for our clients, as to provide a suitable plant layout.

Q4. What is the payment term?

A4. We use T//T as the payment term.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!