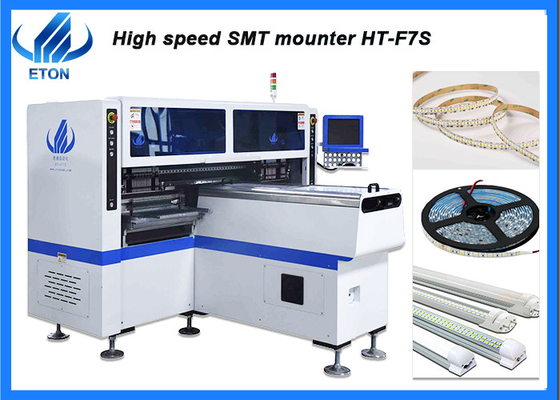

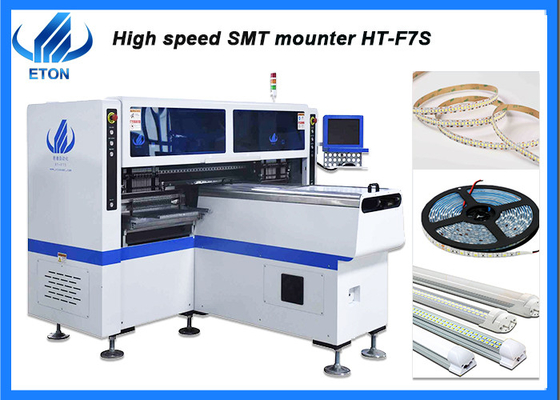

Professional highspeed capacity reach 180000CPH SMT pick and place machine

Production description

Dual-arm professional high-speed mounter

Double module, vision system with camera 5 sets, high precision mounting.

The equipment software is independently developed by the company. And the machine is suitable for semi-automatic production line and full- automatic production line.

Feeder 68pcs nozzles 34pcs

Machine parameter

| Dimension |

2700*2300*1550mm |

| PCB size |

Max 1200*300mm |

| PCB thickness |

Adjustable pressure pneumatic |

| camera |

5sets |

| Repeat mounting precision |

0.02mm |

| Power |

380AC 50HZ |

| Feeder |

68pcs |

| Head |

34pcs |

Introduction to structure and function of Mounter

Frame is the foundation of the machine. All transmission, positioning organization and feeder are firmly fixed on it. Therefore, it is necessary to have satisfactory mechanical strength and rigidity.

PCB transmission and bearing organization - the transmission organization is an ultra-thin belt transmission system placed on the guide rail. Its function is to send the PCB to the predetermined position, and then send it to the next process after pasting.

Drive system - it is the key organization of the mounter and the primary index to evaluate the accuracy of the mounter. It includes XYZ transmission layout and servo system. Its functions include supporting the movement of the mounting head and supporting the bearing plane of PCB.

Application

SMT production line

we can provide our custmers production line solution and equipment, according to our customers needs.

Package

In our packaging process, the first step is to wrap a layer of foam cotton and film, the second step is to vacuum the bag, the third step is to film, the fourth step is to fix the four corners with wooden piles, and finally fix the wooden box. Loading is completed. Every step of our packaging process is strictly controlled, with full records of salesmen, and keep in touch with customers at any time.

Service

Our customer

The following picture shows our engineers stationed in the customer's factory and will not leave until the customer's factory line layout is completed

FAQ

Q: If machine have any problem after I receive it , how can I do?

A: During the warranty period, we will replace it for you free, or we can arrange a process engineer to repair it for free

Q: About technical offer

A: As for machine operation, we will arrange engineers to go to your factory for installation and teaching after you buy our machines.

If you have engineers who have been involved in the installation of SMT equipment, we can teach you how to install it online.

Q: Is the software for these machine in English?

A: Yes. Our software is independently developed, there are two version in English and Chinese.

Q: This is the first time I use this kind of machine, is it easy to operate?

A: There is English manual or guide video that show you how to use machine. If you still have any question, please contact us by e-mail/ Skype/ phone/ wechat/ online service.

Q: What products you sell?

A: Our company deal in the following products:

SMT equipment and accessories: pick and place machine, stencil printer machine, glue dispenser, conveyor, feeders, SMT nozzles,etc.

Q:What is the difference between semi-automatic production line and full-automatic production line?

A:In short, fully automatic production lines are expensive, but require less labor. Semi-automatic production line is more affordable, but the labor will be more than the automatic line

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!