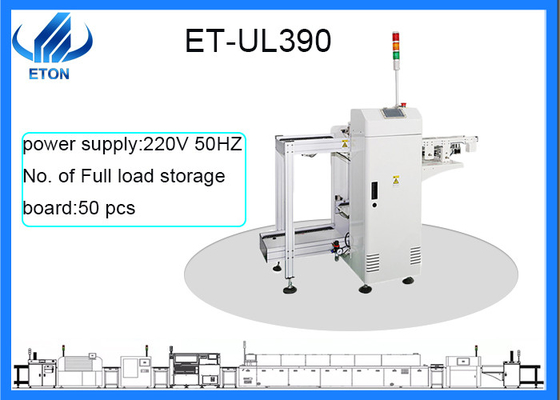

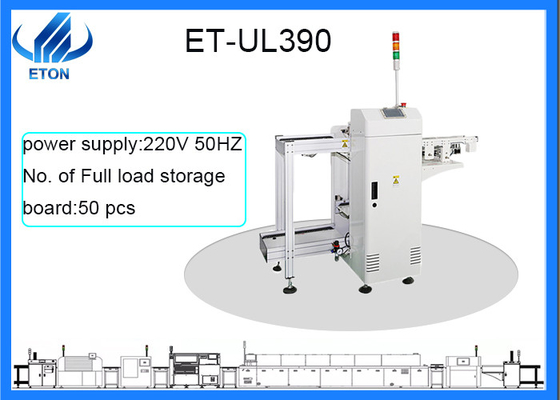

SMT MACHINE ET-UL390 loader machine

SPECIFICATION

Item:ET-UL390 loader machine

Dimension:L2200*W920*H1200mm

Frame:Special aluminum profile guide rail and special thousand bird type plastic chain

Lift:120W Taiwan brake motor drive uses ball screw to make Magazine stepping up and down

Structure:Pneumatic clamp structure

0.9M long push plate Conveyor:1 set

Maximum size of PCB:L530*W390

Turnover box specifications:(L)535*(W)460*(H)565mm

Direction:Left to right / right to left

Lift platform pitch selection:10,20,30,40

Closing function:Automatic

Operation control panel:Display control true color touch screen

power supply:220V 50HZ

No. of Full load storage board:50 pcs

Automatic trigger features:

1.microcomputer control, stable and reliable work

2.Fuji Button or touch screen two control panels to choose, man-machine dialogue is convenient

3.a number of sound and light alarm functions

4.can use the standard material box, strong versatility, can place three material shelves

5.according to the PCB thickness, can set the material shelves up and down step

6.material machine built-in push plate mechanism

7.with automatic counting function,convenient for production statistics, with signal communication structure, can be connected with other machines on-line

Safe Operation Requirements:

1. Boot, please pay attention to work music, air pressure is correct.

- during white-light operation, do not press the emergency button unless the button is pressed in an emergency.

- it is prohibited for a staff member to be attached to a machine frequently or on a machine.

- lifting trolley, do not put your hand around the frame

- attention to adjust the plate spacing on the rack, wide easy to lead to fall off the board, tight easy to lead to card board

Pre-boot:

1. power on. Air Source. Turn on the power switch.

2. 1,2adjust the grade of the track, so that it is consistent with the grade of the PCR plate. Three send board step number area Out Board Point buy set

3. step set: press the button to select Pitch 12342.

4.out board adjustment:

4.1manually adjust the push rod in the middle of the PCB to be produced.

4.2make sure the machine can send the board smoothly 4.3press the White Key

4.4press the return key

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!