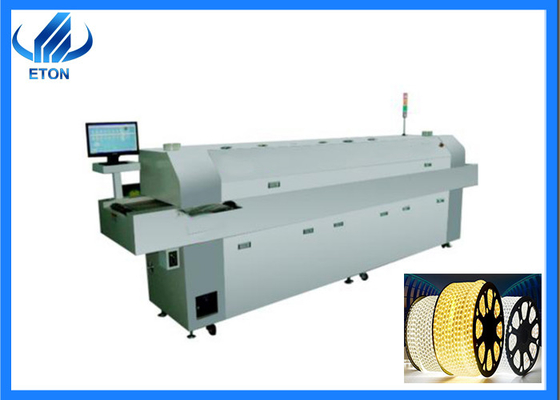

SMT PCB Assembly Line led strip light Reflow Soldering Oven Machine

About smd reflow soldering machine:

SMT reflow soldering is through the solidification of high temperature solder, thereby connecting the circuit board and SMT surface mount components together to form an electrical circuit

Features

1.energy -efficient heating system uses 110-volt nickel-Swedish branded heating tubes.

2.imported large current solid state relay non-contact output ,safe and reliable.

3.Japan NKW using sophisticated temperature controller with fuzzy control and PID imports intelligence operation.

4.Japan STK high temperature and high motor ,smooth transport wind ,vibration ,no noise.

5.the up furnace can be open ,easy to clean the furnace.

6.fault diagnosis ,sound and light alarm.

7.from room temperature to set the temperature for about 15 minutes.

Machine details

|

Product model

|

ET-R8S

|

|

NO. of heating zone

|

Upper 8 hot air heating, lower 8 hot air heating

|

|

Length of heating zone

|

3000MM

|

|

heating method

|

Full hot air circulation

|

|

NO. of cooling zone

|

2

|

|

PCB maximum width

|

350MM

|

|

Conveyor belt height

|

880±20mm

|

|

Delivery method

|

Mesh belt drive + Chain (optional)

|

|

Conveyor speed

|

0-1500mm/min

|

|

power

|

Three-phase five-wire AC:380V 50Hz

|

|

Starting power

|

20kw

|

|

Working power

|

5KW

|

|

Temperature control method

|

PID control + SSR drive

|

|

Temperature control method

|

±1℃

|

|

Abnormal alarm

|

Abnormal temperature alarm

|

|

Machine dimensions(L*W*H)

|

4200×700×1300

|

|

Machine weight

|

600KG

|

Precautions during operation:

1. SMT reflow soldering should only be performed by licensed operators, technicians, engineers or other trained personnel.

2. Before starting SMT reflow soldering, confirm whether the power supply and origin of the machine can work normally.

3. When SMT reflow soldering is running, do not put your hands and feet in the safety cover.

4. During the operation or adjustment of SMT reflow soldering, two or more people are not allowed to operate the same machine.

FAQ

1.Who are we?

Our company is located in Shenzhen, with 52000SQM factory in Jiangxi, China, and we have our own factory to produce SMT High-speed pick and place machine and SMT equipment.

2.What products do we carry ?

Our company's main SMT equipment and related consumables and auxiliary materials, such as SMT printers, SMT placement machines,reflow soldering oven, conveyor, loader/unloader, solder paste mixer etc., can be a one-stop purchase of a full range of products.

3.What can we do for you?

We can provide you with a complete set of SMT solutions, and provide you professional technical support and services.

4.Why choose us?

China's leading SMT equipment supplier has a professional service team and technical support. All products undergo strict quality control before leaving the factory to provide you with the most cost-effective production plan.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!