High Speed Multifunctional Double Module 40 Nozzles Pick And Place Machine

Machine information

1. Machine highlights

(1) high speed multi modular head, apply to ultra small chip 0201-10*10mm large chip, wider component range

(2) improve recognition performance, size up to 40*40mm.

(3) each module 20 spindles, both high speed and intelligent with light compact design.

(4) each placement head with independent detection function, improves the stability of the equipment and the reliability of the product.

(5)adopt high end magnetic linear motor, servo system and multi function modular head, the capacity increased by 25% compared with traditional machine, optimum placement speed reach 120000 CPH.

2. flexible production

(1)fixed line scan camera: components with size less than 10*10 mm, or height less than 6mm can be used to high speed and high precision identification

(2)MARK recognition: high precision mark recognition system, adopt 3-color illumination recognition, apply to any shape mark and lens, wider range of applications.

(3)docking cart, smart double head tape feeder

3. high reliability

(1)brand new self-developed high precision placement head

(2)combine high accuracy, mark recognition camera with fixed flight vision camera, ensure placement accuracy

(3)the placement head adopt independent vacuum detection improve placement performance

(4)off-line programming, save time of changeover cycle

(5)software AI intelligent learning function and automatic optimization function

4. transmission system structure

(1)two gantry, 120 spindles * 2 gantry, total 40 spindles

(2)flexible PCB handling capabilities, double rail, both gantry can mount the same large PCB at the same time, realizing flexible production

(3)flexible wiring through modular placement heads and various production modes.

Parameter

| model |

YT 402 |

| PCB size |

MAX size: 500*450 mm(single PCB)

500*300 MM(double PCB)

MIN size: 50*50 mm

|

| PCB thickness |

0.5-4.5 mm |

| PCB clamping |

Cylinder clamping, track width adjustable |

| rail |

2 rail, 2 gantries( rail 1,4 are fixed rail) |

| system |

Windows 7 |

| software |

R&D independently |

| Production management MES system |

Customized(option) |

| Off-line programming |

available |

| No. Of camera |

4 set (digital camera) |

| Bottom vision camera recognition |

| Vision alignment+ mark correction |

| Repeat precision |

±0.02 mm |

| Mounting height |

≦6 mm |

| Mounting speed |

120000 CPH(optimum speed) |

| Components range |

Min 0201-10*10 mm packages and IC etc |

| power |

380 AC 50 Hz 6 KW |

| Operation environment |

23℃±3℃ |

| Transmission direction |

Standard: single direction |

| Transmission mode |

Online drive |

| Position mode |

optical |

| Air consumption |

0.4-0.6 mpa()4-6 kgf/cm2) 150 N/min |

| Electrical control |

Independent research and development by ETON |

| Motion control card module 1 set |

| X,Y,Z Axis drive way |

High end magnetic linear motor+ servo motor |

| No. Of feeder station |

Double side docking cart slot 32 PCS, tape reel packages : 64 PCS(single side docking cart slot 16 PCS, tape reel package: 32 PCS),freely switching between docking cart and IC tray feeder |

| No. Of heads |

Double side: 40 PCS(single side: 20 PCS) |

| Feeding way |

Intelligent double head feeder |

Certificate

Quality equipment:from R&D to production by ETON, each process strict control, quality assurance;9 inventation patents, 112 practical patents, 12 software copyright;

Market

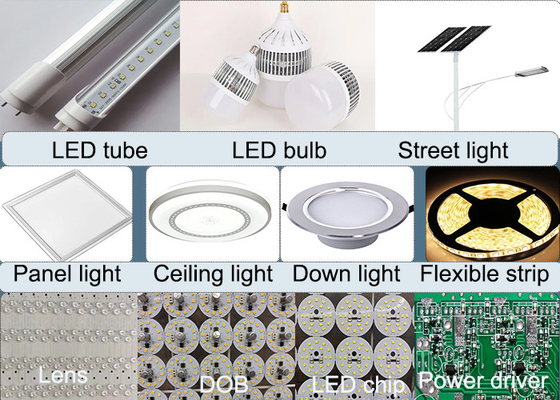

Suitable machines: various machines are apply for various products, DOB, LED bulbs, lens, streetlight, ceiling light, spotlight, flexible strip, electric board, power driver, household application, display min component 0201, highest capacity reach 500000CPH;

Complete service: local engineers and office provide freely training and installation,software freely upgrade whole lifetime;

Market and export: Help 80% of domestic LED factories to build production lines; Foreign exports to more than 20 countries and regions, such as Turkey, India, Egypt, Brazil, Russia, Pakistan, South Korea, etc

Exhibition

ETON actively participates in various exhibitions at home and abroad, and lets our products show up in front of our customers.

Service

Maintenance period : 1 YEAR

Visit customers regularly and gather information

Provide latest information about technology and equipment

Overseas engineers teach equipment operation

FAQ

1. Do you provide the complete production line machine?

Yes, of course. We provide the whole production line machine, including solder paste printer machine, conveyor, pick and place machine reflow oven.

2. What are the main appliance about the pick and place machine?

We have many different machine, and different machines apply to different appliance. The main products include bulb, tube, flexible strip, panel light, down light,street light,ceiling light, wall washer light etc.

3. How about the operation software language of the machine?

Our software are Independent R&D by ourselves with 2 language( English and Chinese).

4. What’s the terms of payment?

T/T is OK. You can choose FOB Shenzhen.

5. Who are your main clients?

Our production have exported to more than 20 countries and regions, including South Korea, India, Egypt, Turkey, Russia etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!