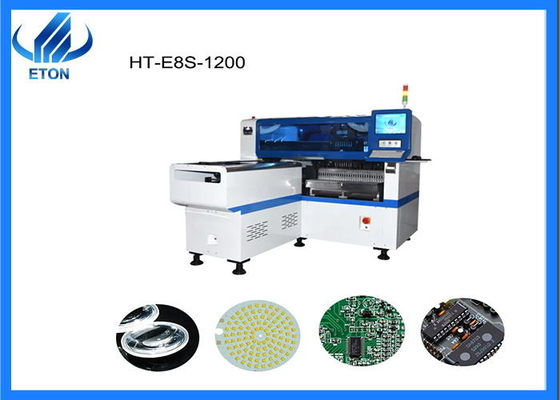

Parameter

| Product name |

SMT mounting machine |

| Model |

HT-E8S-1200 |

| Length(mm) |

2550 |

| Width(mm) |

1650 |

| Height(mm) |

1550 |

| Total weight(kg) |

1700 |

| Mounting speed |

45000 CPH |

| PCB size(mm) |

Max:1200*500

Min:100*100

|

| PCB thickness |

0.5-5mm |

| Mounting component height |

<15mm |

| PCB clamping |

Adjustable pressure pneumatic |

| Systems |

Windows 7 |

| Software |

R&D independently |

Function Description

Vision system

The SMT mounting machine visual recognition system is equipped with two sets of imported cameras, one for mark correction and the other for flight visual recognition alignment. The two cameras cooperate with each other, which can not only make the program of mounting PCB on this basis, but also automatically identify and replenish materials.

Productive power

While producing a variety of PCBA, it can also mount lenses, IC and various special-shaped components.The minimum mounting components range is 0402, the maximum mounting components range is 15mm, and the maximum width span of the components is 17mm,The production capacity can reach 45000 CPH (The optimum conditions).

Features

- Single module machine

- SMT mounting machine Mounting components:LED,capacitors,resistors,IC,shaped components,etc.

- Component:min size 0402; max. Height 15mm

Exclusive patented technology

- Electronic feeder feeding system

- Vision alignment flight identification,Mark correction

- Non-stop material re-loading function

- Auto-optimization after coordinates generated,etc

The advantages of SMT patches are as follows:

1. Small size and light weight

The volume and weight of SMT components are only about 1/10 of those of traditional plug-in components, which is convenient for mounting. Generally, after SMT chip processing, the volume of electronic products can be reduced by 40% to 60%, while the weight can also be reduced by 60% to 80%.

2. Increased efficiency and reduced costs

SMT patch processing is easy to achieve automation, improve production efficiency, save materials, energy, equipment, manpower, time, etc., and reduce costs by 30% to 50%.

3. High reliability and strong seismic resistance

4.Good high-frequency characteristics, reducing electromagnetic and radio frequency interference

5. Low solder joint defect rate

6. High mounting density

Differences and connections among PCBA, SMT, and PCB

⭐ PCB: Acronym for "Printed Circuit Board" , is a carrier used to support electronic components and provide wiring. It is only a semi-finished product and cannot be directly put into use. It must undergo SMT mounting and DIP plug-in processing.

⭐ SMT: Acronym for “Surface Mounted Technology” . It is a circuit assembly technology that uses professional processes to mount electronic components onto a PCB and solder them together.

⭐ PCBA: Acronym for "Printed Circuit Board Assembly", refers to the one-stop processing process where printed circuit boards (PCB) undergo raw material procurement, followed by SMT surface pick and place machine, DIP plug-ins, testing, and finished product assembly.

Note: The processing sequence of an electronic product should be as follows: PCB → SMT → PCBA.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!