Product Description

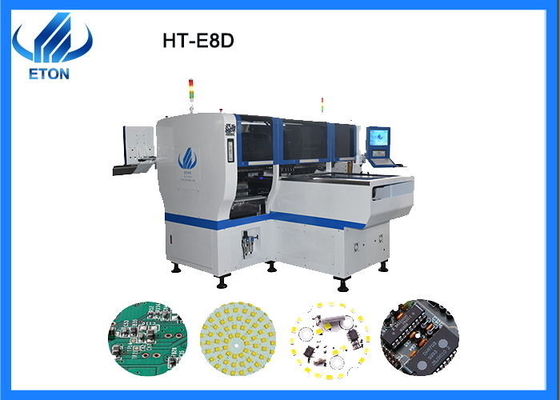

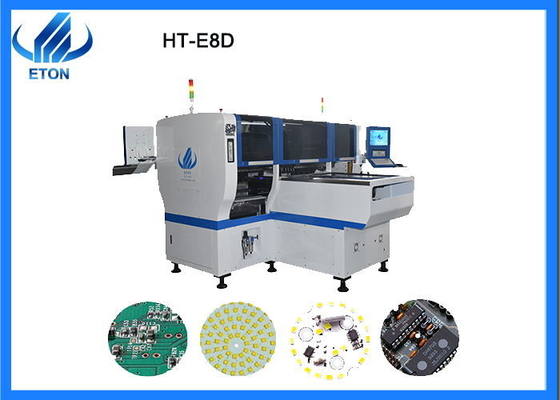

The HT-E8D-1200 is a dual module maglev multi-function high-speed SMT mounter. This model of dual module is controlled by two systems, and each module is controlled by a set of independent programs. The two modules are independent of each other, which means that two PCB can be produced simultaneously and two different products can be manufactured.

Parameter

| Product name |

SMT mounter |

| Product model |

HT-E8D-1200 |

| Length |

3150mm |

| Width |

2250mm |

| Height |

1650mm |

| Total weight |

2500kg |

| PCB thickness |

0.5-5mm |

| PCB clamping |

Adjustable pressure pneumatic |

| PCB size |

Max:1200*300mm

Min:100*100mm

|

| NO.of camera |

4 sets |

| NO.of nozzles |

24 PCS |

| NO.of feeder station |

48 PCS |

Role of machine components

Ø MARK camera:Perform the installation procedure for the PCB board by scanning the mark point as a benchmark.

Ø Flight identification camera: Take photos of components taken by the mounting head of the SMT mounter, compare the mounting procedures made by the previous mark camera, and calculate whether compensation is needed to mount positive components

Ø Linear magnetic levitation motor: The rotor generates a magnetic field through external power connection. The stator itself is a permanent magnet. The interaction between the rotor and the magnetic poles causes the mounting head to repeatedly move.

Ø Grating ruler: It uses the optical principle of grating to work, and is a measurement and feedback device. It has high detection accuracy and fast response speed, which to some extent determines the accuracy of head mounting.

Ø Linear guide rail: used to support and guide moving parts (mounting heads, transportation platforms), and perform high-precision repetitive movements in the specified direction.

Ø Nozzle:The suction nozzle of a multifunctional placement SMT mounter is generally composed of alloy and ceramic, but it is easy to break.

Suction nozzle type

|

3014

|

3014,4014,2020, small resistance, capacitance, etc |

| 3528 |

3528,5630,5730, small resistance, capacitance, etc |

| 5050 |

5050, IC, heterosexual components, large resistance, capacitance, etc |

FAQ

Q1: Is there any difference between your company's HT-E8S-1200 and HT-E8D-1200?

A: The two SMT mounter are functionally identical, except that the E8S is a single mode group SMT mounter, and the E8D is a dual mode group SMT mounter. The E8S has a production capacity of 45000 CPH, and the E8D has a production capacity of 90000 CPH, twice that of the E8S.

Q2: What are the differences between multifunctional SMT mounter and dedicated SMT mounter in the applied products?

A: The multifunctional machine is suitable for a variety of products, such as ball bubbles, display screens, drives, etc., with higher mounting accuracy, but at the same time, the mounting speed is slower compared to dedicated opportunities; The dedicated machine is mainly used for linear products such as light tubes and soft light strips, with less stringent requirements for mounting accuracy and faster mounting speed.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!