Features

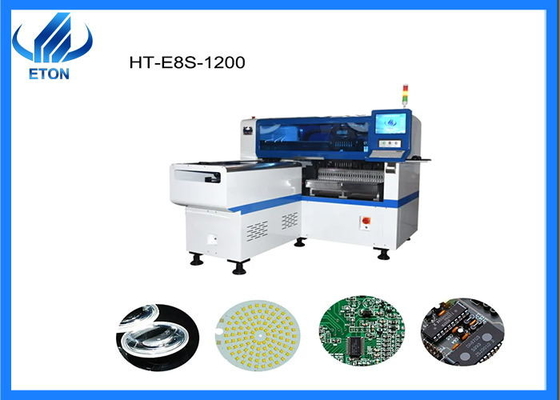

1,The SMT mounting machine is single module equipped with 12 suction nozzles and 28 feeders, each suction head controlled by a servo motor, and the two work together. PCB boards with different angles can be installed, such as the circular state of the light bulb.

2,The PCB board is pneumatically fixed with adjustable pressure, which has the advantages of simple structure, reliable and stable action, large output force, convenient installation and maintenance, and can be fireproof and explosion-proof.

3,Mounting components range: Belt mounted lamp beads, lenses, capacitors, resistors, IC, and various special shaped components. Minimum mounting 0402 elements, maximum mounting range: 15mm.

Parameter

| Product name |

SMT mounting machine |

| Product model |

HT-E8S-1200 |

| PCB size |

Max:1200*500mm

Min: 100*100mm

|

| PCB thickness |

0.5-5mm |

| PCB clamping |

Adjustable pressure pneumatic |

| Mounting mode |

Group picking and separate placing ,separate to pick and separate to stick |

| Mounting height |

<15mm |

| Mounting precision |

±0.04mm |

| Mounting speed |

45000CPH |

| Components space |

0.2mm |

| Feeding way |

Electric feeder with double motor |

| X,Y,Z Axis drive way |

High-end magnetic linear motor and servo motor |

SMT production line

The whole SMT production line machine mainly include Loader machine, full automatic stencil printer, pick and place machine, conveyor , reflow oven, unloader machine

Stencil printer:Put the solder paste on the PCB board

Conveyor: transmission the PCB board to pick and place machine

Pick and place machine:mounting the components on the PCB board

reflow oven:heating the PCB board

Certificates

Our company has obtained 9 invention patents, 12 software Copyrights and 112 practical patents

Patent number: ZL 2011 2 0237740.9 ZL 20 11 2 0334606.0

ZL 2012 2 0178869.1 ZL 2012 2 0415505.0

ZL 2012 2 0415044.7 ZL 2012 2 0415356.8

ZL 2012 2 0415061.0

FAQ

Q1:What are the factors that affect SMT mounting machine productivity?

A:The factors affecting the production capacity include: the time of entering and exiting the plate, whether the plate is received and delivered in a timely manner, whether the material is delivered in a timely manner, the number of plates assembled, the number of heads used, the type of components, and the number of components.

Q2:Is there any difference between your multi-function SMT mounting machine and a specialized SMT mounting machine?

A: Multifunctional machines can be installed with a variety of products, and special machines are best equipped with linear products such as lamp tubes and light strips. The main reason is the difference in mounting technology. The mounting technology for specialized machines is group to pick and group to place,while the mounting technology for multi-function machines is group picking and separate placing ,separate to pick and separate to stick. This is because the head of multi-functional machines is controlled by an independent motor.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!