Magnetic linear motor SMT Mounting machine HT-E8D 90000CPH speed for All LED lighting

Parameter

| PCB size |

Max:1200*300mm Min: 100*100mm |

| PCB thickness |

0.5-5mm |

| Mounting rail |

Two rail |

| Mounting mode |

Separately picking and separately placing,

Group picking and separately placing

|

| Mounting height |

<15mm |

| Mounting precision |

±0.04mm |

| Mounting speed |

90000CPH |

| Components space |

0.2mm |

Why choose HT-E8D?

-

Double Modules and dual systems:Two different products can be produced at the same time

-

Accurate recognition: four sets of cameras (two sets of flight recognition visual alignment + two sets of MARK correction)

-

High speed: 24 nozzles work efficiently at the same time

-

Multi-function placement machine: used in various home appliance controllers, various lamps, drives, displays, lenses and so on

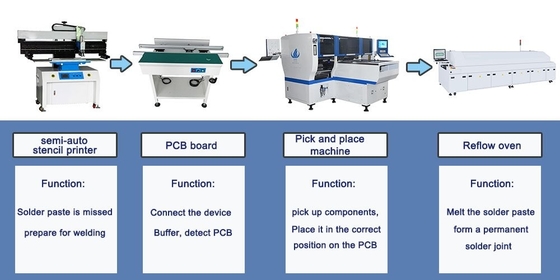

Advantage of SMT machine

1.High assembly density, small size and light weight of electronic products

2. High reliability and strong earthquake resistance

3. Good high frequency characteristics

4. It is easy to realize automation and improve production efficiency

5. Reduce costs

ETON Profile

Since its establishment in 2011, ETON has been committed to the development and production of SMT placement machines and peripheral equipment in 2007.

* Strong reach and develop technology team, support machine upgrade continuously, support client strong technical support

* Rich experience in SMT Industry Line. ETON set up more than 10 years, we are leading manufacturer of SMT machine in China

* Strong production capacity, ETON have more than 50000 square meter Industrial park in Jiangxi Province, machine capacity more

than 50 units/month

* Good and professional service. Provide engineer Door-to-door service, support video online training, video training share, free

replaced machine core part during warranty. And also we could provide professional SMT line solution.

Service

※ Maintenance period 1year

One year warranty, during warranty, any parts need to be repaired and replaced will be free.

※ Software and hardware lifetime maintenance

Free upgrade software, software is Reach and develop by ETON, so we support whole lifetime free upgrade updates.

※ Visit customers regularly and gather information

Visit clients regularly. We attend different exhibition in different cities every year, at the same time, we will visit local clients and support our service and collect and feedback customer suggestions in time.

※ Provide latest information about technology and equipment

We give professional technology suggestion with our clients.And share the updates news to our clients

FAQ

Q: What is your actual speed of your products?

A: For the actual speed of the machine which is constrained by many factors,that relatedto the number of the components, the time to send PCB board and receive the board that will have influence on the speed when in production, and is decide for the actual products and needs.

Q: Can I go and see if you have sold the equipment to India?

A: Yes, we have sold our machine in India, but for the fact we can't decide it for our customer, but I will try to contact our customer. Hope you can understand, because no one wants their competitors to visit their manufacturing site.

Q: It’s hard to use the machine?

A: Machine is very intelligent and easy to operate, like the intelligent phone, also the software is made by our company, so we know how to make it more intelligent and operate friendly.

Customer's Story

Client: Turkish client

City: Istanbul

Product: Led bulb/panel lights

The client used to do SKD, and plans to do SMT patch in 2021.The client need full automatic SMT production line with high capacity, but there are many components that to be mounted on the PCB board. After understanding these, ETON recommend purchasing two pick and place machines, one for LED chip and one for IC. , resistors, bridge rectifiers, etc., It’s can improve production capacity effectively. In October 2021, the client decided to purchase the full-automatic production line for the production of bulbs and panel lights, and completed the installation at the end of 2021. Now the production is going very smoothly. In the process, client learned that ETON has been focusing on SMT pick and place machine for more than ten years, and has professional R&D team, factory, sales and after-sales engineers, so they are very trusting and satisfied with ETON.In the new year, the client has launched a new plan, and the second ETON SMT production line is in the manufacturing stage and waiting to be shipped.Its mounted components mainly include LED chip , ic , bridge , socket , resistor, customer bulb size 12w, 18w, 24w and 30w, PCB board size: 12w: 240*240mm, 18w: 235*295mm, 24w: 267*267mm , 30w:269*269mm

Contact David

Whatsapp/Wechat/Tel: +86 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!