LED lighting SMT Mounting Machine mount components on PCB board 250000CPH chip mounter

The main parameter

| Length |

2700mm |

| Width |

2300mm |

| Height |

1550mm |

| Total weight |

1700kg |

| PCB Length width |

Max: 1200*330mm Min: 100*100mm |

| PCB Thickness |

0.5-5mm |

| PCB clamping |

Adjustable pressure pneumatic |

| Transmission speed |

>500mm/sec |

| Conveyor transmission |

Max length: 1200mm |

| Repeating Mounting precision |

±0.02mm |

| Component space |

0.5mm |

| Component height |

≤5mm |

| Transmission direction |

Single (left→ right or right→ left) |

| No. Of feeders station |

68PCS |

| No. Of head |

68PCS |

| Operating environment |

23℃±3℃ |

| Power consumption |

6KW |

| Transmission mode |

Online drive |

| Positioning way |

Optical |

| X, Y, Z Axis drive way |

High-end magnetic linear motor and serve motor |

| Feeding way |

Electric feeder with double motor |

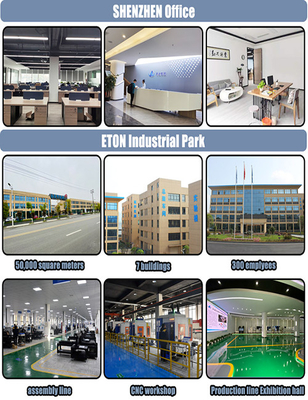

ETON Advantages

Efficient team: The best suggestions of full SMT lineequipment according to your budget and site.

Competitive price: We are directly manufacture of the ETON pick and place machine, so we can give you the best competitive price with high quality materials.

High quality: We have strictly quality control during allproduction from raw materials to the finished machine.

High efficiency: Allmachines parts are made byourselves, so it" s convenient to control the timeschedule and quality timely.

Service

Since its establishment in 2011, ETON has been committed to the development and production of SMT placement machines and peripheral equipment in 2007.

* Strong reach and develop technology team, support machine upgrade continuously, support client strong technical support

* Rich experience in SMT Industry Line. ETON set up more than 10 years, we are leading manufacturer of SMT machine in China

* Strong production capacity, ETON have more than 50000 square meter Industrial park in Jiangxi Province, machine capacity more

than 50 units/month

* Good and professional service. Provide engineer Door-to-door service, support video online training, video training share, free

replaced machine core part during warranty. And also we could provide professional SMT line solution.

Development trend of LED placement machine

LED placement machine is developing towards higher precision

The placement machine accuracy refers to the mechanical accuracy of the placement machine's X, Y axis navigation movement and the Z axis rotation accuracy. The placement machine adopts precise mechatronics technology to control the mechanical movement to grab the components from the feeder and place them on the circuit board precisely and reliably after being centered by the calibration mechanism. In order to produce products with higher performance, one of the first major challenges is to improve the placement accuracy of the placement machine as much as possible.

In common LED packaging technology, the connection between chip electrodes and support pins is generally achieved through interconnection with gold wires, but gold wire breakage has always been one of the common causes of failure. Abnormal gold wires in LED lighting applications are the culprit for common problems such as dead lights and large light decay. The dead light can be roughly divided into two situations, one is not bright at all, the other is not bright when it is hot, it is bright when it is cold, or flickering. The main reason for not lighting up is that the electrical circuit is open, and the reason for flickering is due to weak soldering or poor contact of the gold wire.

With the introduction of flip-chip soldering technology, the connection between the two can be connected through more stable metal bump solder balls, which saves costs and greatly improves reliability and heat dissipation. LED has the advantages of long life and other advantages. Compared with the traditional packaging technology using gold wire interconnection, the flip-chip welding technology can give full play to the advantages of LED. LED flip-chip welding technology realizes the single-chip and multi-chip modules. Die-bonding glue package has many advantages such as high brightness, high light efficiency, high reliability, low thermal resistance, and good color consistency.

LED gold-free packaging is commonly known as "no packaging" and "free packaging" in the industry. This process uses the direct SMT bonding of the flip chip and the circuit board, omits the SMD packaging process, and directly attaches the flip chip to the circuit board or the carrier by the SMT method, because the chip area is much smaller than the SMD device, so This process requires very sophisticated design.

In the future, the LED placement machine will be directly applied to the flip-chip non-encapsulation process on the basis of improving the accuracy. This will be a small revolution in the LED process, which can save a lot of packaging costs, and greatly increase the production cost and shorten the production cycle. It makes LED products really enter the general lighting market with high performance and low price. Applying the LED placement machine directly to the LED manufacturing process has the potential to become a future technology trend.

Contact David

Whatsapp/wechat/tel: +86 13827425982 / 0086 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!