High speed 68 feeder LED tube mounting SMT pick and place machine

Shipping and Delivery

Land transportation: suitable for inland countries and it is affordable;

Air freight: for urgent good, and it is the most expensive transportation way;

Shipping: It’s suitable for heavy goods, and the convenience and lower cost of shipping which is easy for clients to accept the arrival time of the goods.

Description

- High-end magnetic linear motor+ servo motor

- Apply to the 0.6 M, 0.9 M, 1.2 M rigid PCB and 0.5 M, 1 M LED flexible strip. Producing with 4 types of materials with high capacity. available for board with any proportion of LED chip and resistor.

- Two mounting modules, 17 nozzles for each mounting part, part A or part B can be mounted separately or synchronously.

- Exclusive patent technology: Group to pick and group to mount.

IPC9850 Capacity: 150000-180000 CPH

Patent number: ZL 2011 2 0237740.9/ ZL 2011 2 0334606.0/ ZL 2012 20178869.1/ ZL 2012 2 0415505.0/ZL 2012 20415044.7/ZL 2012 2 0415356.8/ ZL 2012 2 0415061.0

Technical parameter

| Model |

HT-F7S |

| Dimension |

| Length |

2700mm |

| Width |

2300mm |

| Height |

1550mm |

| Total Weight |

1700kg |

| PCB |

| PCB Length Width |

Max:1200*330mm Min:100*100mm |

| PCB Thickness |

0.5-5mm |

| PCB Clamping |

Adjustable pressure pneumatic |

| Mounting Mode |

Group to take and group to mount |

| O.S. |

| System |

Windows7 |

| Software |

R&D independently |

| Display |

Touch screen monitor |

| Input Device |

Keyboard, Mouse |

| Vision System |

| No. of Camera |

5 PCS ( Digital camera) |

| Vision alignment, MARK correction |

| Mounting Precision |

±0.02mm |

| Mounting Height |

≦5mm |

| Mounting Speed |

150000~180000 CPH |

| Components |

LED 3014/ 3020/ 3528/ 5050 and capacitors, resistors, bridge rectifiers, etc. |

| Components Speed |

0.5mm |

| No. of Feeders Station |

68 PCS |

| No. of nozzles |

34 PCS |

| Power |

380AC 50 HZ |

| Power Consumption |

6kw |

| Operating Environment |

23℃±3℃ |

| Transmission Speed |

Max Length :1200 mm |

| Transmission Direction |

Single(left→ right or right→ left) |

| Transmission Mode |

Online drive |

| Position Mode |

Optical |

| Gas consumption |

0.4-0.6mpa (4-6kgf/cm2)600N/min |

| Electrical control |

Independent research and development by ETON |

| Motion control card module 1 set |

Independent research and development by ETON |

| X,Y,Z Axis Drive way |

High-end magnetic linear motor+ servo motor |

| Feeding way |

Electric feeder with double motor |

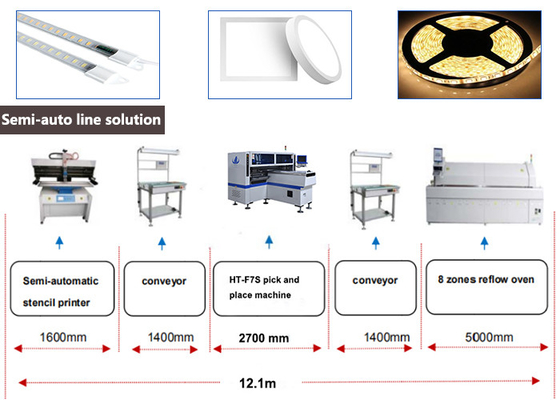

SMT Line solution

A whole semi automatic line which needs several devices for a whole semi production, as semi auto stencil printer machine, conveyor, pick and place machine and reflow oven etc.

The blowing is the function of each machine:

Certificates

As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 200 practical patents, 49 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA,

etc.

Service

- Professional solutions: Provide professional SMT Full line solutions

- Free Warranty: One-year warranty factory service. All parts damaged within the warranty period shall be replaced free of charge

- Free Installation: On-site free installation to ensure smooth production.

- Free Technical Training: Professional training of operating and maintenance.

- Free Technical Support: 7 * 24 technical online support.

- Free Software Upgrade: Offer free software upgrade whole lifetime

FAQ

Q. How many components can your pick and place machine mount in a PCB board?

A. While this is for our clients needs and the size of the PCB board.

Q. What components is your machine mainly mounted?

A. For the multifunctional pick and place machine that can mount IC, LED chip, resistors, capacitors and shaped components like lens. High speed mounter machine mounting components are LED3014/3020/35285050, resistors, capacitors and rectifiers.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!