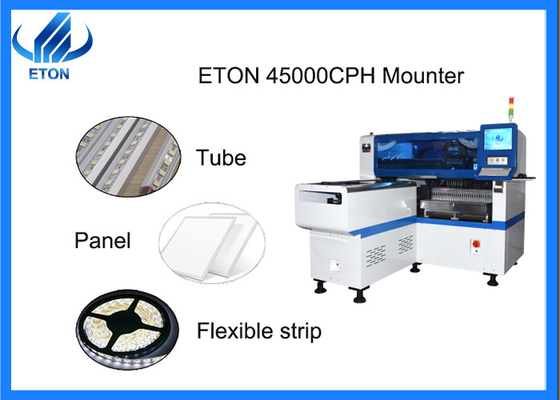

HT-E8S-1200 SMT Mounting Machine magnetic linear motor 45000CPH in production

Technical parameter

HT-E8S-1200 is a smt machine specially designed for lens production with an optimal capacity of 45000CPH.

| Components |

LED chip,capacitors,resistors,IC,RGB,shaped components etc. |

| Total Weight |

1700kg |

| Mounting Height |

<15mm |

| PCB Thickness |

0.5-5mm |

| Display |

Touch screen |

| Mounting Mode |

Group picking and separate placing,separate picking and separate placing |

| Software |

R&D independently |

| Position Camera |

Vision for the flight identification + MARK correction |

| Input Device |

Keyboard,Mouse |

| No. of Camera |

2 sets of imported camera |

| PCB Length Width |

Max:1200*350mm Min:100*100mm |

| Mounting repeat Precision |

±0.04mm chip |

| Length*Width*Height |

2550mm*1650mm *1550mm |

| Mounting Speed |

45000 CPH(optimum) |

| PCB Clamping |

Adjustable pressure pneumatic |

Machine main part:

Three main components: software, electrical and mechanical.

Machine parts and functions

Mainframe: The brain of a machine that collects feedback signals and processes them before issuing instructions

Electric box: all the circuit of the machine is integrated in the electric box. After external power connection, it controls the running process of the machine together with the host machine

Circuit board: Controls various parts of the machine

Servo motor: after the servo motor is energized, it turns positive and negative, and drives the screw rod to rotate by connecting the screw rod with the coupling, thus driving (mounting head, transportation platform) to do linear reciprocating motion. A servo motor controls a screw.

Linear motor: magnetic linear motor, through external electric connection to make the actuator generate a magnetic field, stator itself is a permanent magnet, moving stator through the interaction between magnetic poles to make the mount head reciprocating motion.

Magnetic grid ruler: non-contact scanning magnetic field, and the analog measurement value into absolute or incremental output signal, high detection accuracy, fast response speed, to a certain extent determines the accuracy of head mounting.

Linear guide rail: used to support and guide the moving part (mounting head, transport platform), according to the specified direction to do high precision reciprocating movement

Stepper motor: the track width is adjusted by adjusting the motor to drive the belt connecting screw, so as to be suitable for the installation of different circuit boards of customers. The transport motor drives the belt, which drives the circuit board.

SMT Production Line

The semi-automatic production line

Solder paste printing machine,conveyor, Pick and Place machine, reflow oven.

The full-automatic production line

PCB Loader, conveyor, transplanting machine, buffer frame, automatic printing machine, pick and place machine, belt transport guide rail, reflow oven, PCB Un-loader.

Company advantages

We had building a long-term partnership with some strong factories!

We specialize in this field for 20 years.

We have our own professional designers.

We have 50,000 square meters of industrial park.

Exhibition

Our company participates in many exhibitions at home and abroad every year,

You will see ETON's booth in some well-known large-scale exhibitions in China, including large-scale exhibitions held in Shenzhen, Guangzhou, Chongqing, Shanghai and other places.

Foreign exhibitions include exhibitions in more than 20 countries including Mumbai, Delhi, Egypt, Turkey, and Vietnam.

FAQ

1.Why do we adopt the smart electronic feeders?

Our machines adopt the smart electronic feeders which are more stable,universal and intelligent.

The feeding speed of electronic feeder is faster than the traditional pneumatic feeder.It can avoid the

cast and drop of materials effectively.

2.What the highest production capacity and precision of our LED pick and place machine?

Our machine's production capacity can reach 250000 chips per hour. It is the highest capacity in the

field of LED pick and place machine.Our precision can reach 0.02 mm,we adopt visual positioning,

flight identification mark correction and smart industrial control system.

3.What about our technology patents and certificates?

We have got many technology patents which is global first invention. The global first way:Group picking and group placing. We have rich experience in researching and developing and got SIRA and CE certificate.We are approved as the national high-tech enter

Contact David

Whatsapp/Wechat/Tel: +86 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!