HT-E8S-1200 SMT Mounting Machine magnetic linear motor 45000CPH in production

Technical parameter

HT-E8S-1200 is a smt machine specially designed for lens production with an optimal capacity of 45000CPH.

| Components |

LED chip,capacitors,resistors,IC,RGB,shaped components etc. |

| Total Weight |

1700kg |

| Mounting Height |

<15mm |

| PCB Thickness |

0.5-5mm |

| Display |

Touch screen |

| Mounting Mode |

Group picking and separate placing,separate picking and separate placing |

| Software |

R&D independently |

| Position Camera |

Vision for the flight identification + MARK correction |

| Input Device |

Keyboard,Mouse |

| No. of Camera |

2 sets of imported camera |

| PCB Length Width |

Max:1200*350mm Min:100*100mm |

| Mounting repeat Precision |

±0.04mm chip |

| Length*Width*Height |

2550mm*1650mm *1550mm |

| Mounting Speed |

45000 CPH(optimum) |

| PCB Clamping |

Adjustable pressure pneumatic |

Machine application

Machine widely apply to mounting all kind of SMD components, like led bulb/panel/ down-light/street light/dob /driver/flood light/etc

1. All kinds of LED Lighting board: Bulb, Tube, Lens panel, Solar street light, Strip light, etc

2.Most of driver board: widely apply to mounting MOV, capacitor, 0603/0805/0402 resistor, SOP4/SOP6, Transformer, Terminal, etc

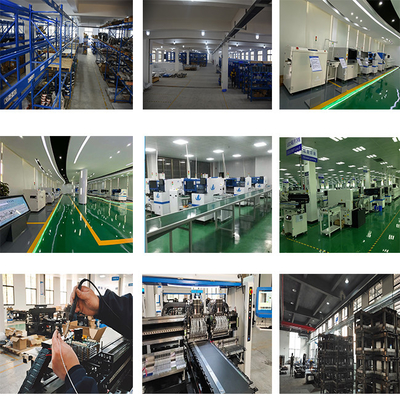

Company advantages

We had building a long-term partnership with some strong factories!

We specialize in this field for 20 years.

We have our own professional designers.

We have 50,000 square meters of industrial park.

Main process

Step 1Stencil printer: Printing solder paste on PCB

Step 2 Pick and place machine: Mounting components on PCB

Step 3 Reflow oven:Heating the solder paste with PCB to welding the components on PCB

Exhibition

ETON has participated in many exhibitions of foreign countries , such as India Mumbai Exhibition, India Delhi Exhibition, Egypt Exhibition, Turkey Exhibition, Pakistan Exhibition, etc and trading with more than 20 countries. Furthermore, we have took part in our domestic large exhibition, like Guangzhou Guangya Exhibition, Shanghai Munich Exhibition, Chongqing LED light Exhibition, etc.

How to guarantee the product quality ?

In SMT Line, our machine need professional operating, that is why we will sent engineer for visit, also worker could check by eye for the obvious problem. Besides, usually many factory will using AOI test machine!

Optical detector: Automatic optical inspection is a device that detects common defects encountered in welding production based on optical principles. AOI is a new type of testing technology that has only emerged in recent years, but it has developed rapidly. At present, many manufacturers have launched AOI testing equipment. When automatic detection, the machine automatically scans the PCB through the camera, collects the image, compares the solder joints tested with the qualified parameters in the database, after image processing, checks out the defects on the PCB, and displays / marks the defects through the display or automatic sign Come out for repair by maintenance personnel.

Contact David

Whatsapp/Wechat/Tel: +86 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!