HIGH SPEED AND PROFESSIONAL PICK AND PLACE MACHINE T9-2S LED STRIP making machine

Features

1.Ultra mounting speed: optimum capacity reach 500000CPH.

2.Mounting head: 4 mounting heads, each mounting head has 34 PCS heads, total has 136 PCS heads

3.Feeder station: total has 136 PCS heads

4.Mounting mode: realize the function of two time picking and once placing; produce four kinds of materials at the same time;

5.PCB size:any length* 250(±10)mm, the max length range is 1M per cycle.

6.Camera: 10 sets of camera, high accuracy recognition vision camera ; no pause to detect the presence or absence of components, component adsorption state, prevent placement errors

Technical parameter

| HIGH SPEED AND PROFEESIONAL PICK AND PLACE MACHINE T9-2S |

| PCB size |

250(±10)mm* any length |

| PCB thickness |

0.1-0.5mm |

| PCB clamping |

Vacuum adsorption, cylinder clamping, track width adjustable |

| Mounting way |

Group picking and group placing |

| Mounting mode |

Double-rail+four groups of placement heads |

| No. Of camera |

10 sets of digital camera |

| Repeat precision |

±0.05mm |

| Mounting height |

≦5mm |

| Mounting speed |

Double side: 500000 CPH, Single side: 250000 CPH |

| Components |

LED 3014/ 3020/ 3528/ 5050 and resistor, capacitor, bridge rectifiers etc. |

| power |

350 AC 50Hz |

| Power consumption |

9.6KW |

| Electrical control |

Independent research and development by ETON |

| Motion control card module 2 set |

| Feeding way |

Intelligent electric feeder with double motor |

| No. Of feeder station |

Double side 136 PCS, Single side 68 PCS |

| No. Of head |

Double side 136 PCS, Single side 68 PCS |

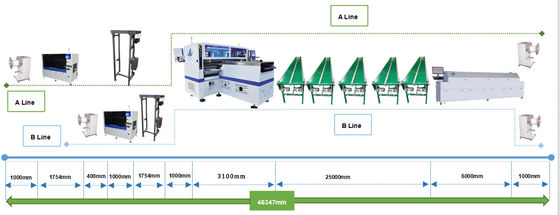

SMT Line solution

The blowing is the function of mainly machine:

-

stencil printer is aim of leaking solder paste or patching adhesive onto the solder pad of PCB to prepare for the welding of components;

-

Pick and place machine is to mount light beads or other surface mounted components at the designated position of PCB board;

-

Reflow oven is to melt the solder paste to fix and bond the components and PCB board.

-

Conveyor is used for the connection between SMT production lines, as well as buffering, testing, testing PCB boards or manual plug-in of electronic components;

-

Why choose us?

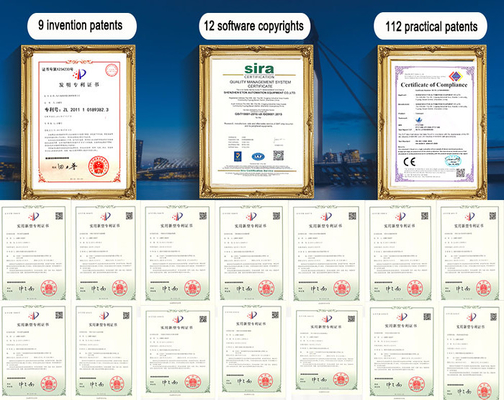

ETON was founded in 2011. Our company is the leading manufacturer of global led light high speed pick and place machine. We have more than 10 years of R&D experience and mature technology and our products are exported to more than 20 countries and regions, including South Korea,India, Vietnam, Tunisia, Iran etc. ETON obtained a number of intellectual property technologies ,including 9 invention patents, 112 practical patents,12 software copyrights. And we have also won many prestigious awards, such as Shenzhen high-tech enterprise, Guangdong high-tech enterprise, China high-tech enterprise, Shenzhen TOP Brand and so on.

Our Exhibitions

Eton has participated in many exhibitions of foreign countries , such as India Mumbai Exhibition, India Delhi Exhibition, Egypt Exhibition, Turkey Exhibition, Pakistan Exhibition, etc and trading with more than 20 countries.

Furthermore, we have took part in our domestic large exhibition, like Guangzhou Guangya Exhibition, Shanghai Munich Exhibition, Chongqing LED light Exhibition, etc.

Package and delivery

All machines shipped abroad will use foam packaging to protect the machines from collisions;

* Secondly, it will be wrapped with stretch film to prevent the equipment from getting damp;

* Vacuum paper packaging and moisture-proof bags keep the machine dry during transportation to prevent moisture;

* Use straps, triangles and nails to fix the machine to prevent damage to the machine during transportation

* Each export machine will be equipped with a strong export-free wooden box.

FAQ

1. What is your usual payment term?

2. Our usual payment term is T/T, that requires to pay 30% in advance, and pay the balance off before the delivery of the goods.

1. How long is the machine maintenance period, whether it is free?

2. The maintenance period of our machine is 1 year and its free for our clients, after the maintenance period we will arrange our engineers to check and test the machine one or two times a year freely.

1. Is the machine easy to operate?

2. Yes, our machine is very intelligent and easy to operate, like the intelligent phone, also the software is made by our company, so we know how to make it more intelligent and operate friendly.

Contact David

Whatsapp/Wechat/Tel: +86 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!