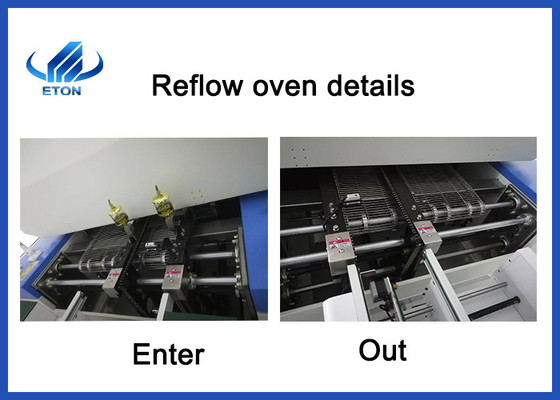

1200KG high-speed air-carrying motor 8 zones reflow oven machine

Description

Reflow soldering technology is not new in the field of electronic manufacturing. The components on various boards used in our computers are soldered to the circuit board through this process. There is a heating circuit inside this device, which uses air or nitrogen After heating to a high enough temperature, it is blown to the circuit board on which the components have been pasted, so that the solder on both sides of the components melts and bonds with the main board. The advantage of this process is that the temperature is easy to control, oxidation can be avoided during the welding process, and the manufacturing cost is easier to control.

Features

- It adopts imported high-speed air-carrying motor direct drive for thermal cycle, low noise, low vibration and high thermal cycle efficiency.

- It adopts Panasonic PLC industrial control products to control the upper and lower computer, which has first-class stability.

- It has a delay switch protection function to prevent the transmission components from deforming due to uneven cooling.

- It has a power-off protection function to ensure the normal output of the PCB without damage after power-off.

- With over-temperature sound and light alarm and emergency braking system.

- All zones are heated separately up and down, independent hot air circulation, independent temperature control, and the temperature control accuracy is ±1℃.

- Modular heating structure can effectively prevent the influence of airflow in the temperature range, ensure that the components are evenly heated, and the lateral temperature deviation is <±2℃.

- The upper furnace body is opened by pneumatic jacking, which is safe ,reliable and convenient for furnace cleaning.

- The heat source of the special durable nickel heating wire, abundant power, rapid heating, less than 20 minutes from room temperature to constant temperature.

- Simplified and traditional Chinese MMI operation interface and artificial intelligence software control greatly facilitate the user's use.

- It has a complete online temperature test curve and analysis, storage, recall and printing functions.

- Dedicated temperature acquisition module, high accuracy and fast speed, with cold junction compensation function.

- Temperature collection adopts RS-485 interface, which is convenient for remote device temperature monitoring.

- With timing automatic shutdown function.

- Host computer control, computer can be cut off, independent control, computer operation, convenient man-machine dialogue, clear interface, intuitive image, can switch between Chinese and English at any time, and various parameter settings realize accurate and fast numerical input.

- Using PLC control, the temperature control is stable and accurate, and the temperature of each zone is individually controlled.

- The motor is imported, high-quality,and high-temperature-resistant, with good structure and good heat dissipation, to ensure its service life and reliability. The direct connection mode connects the wind wheel with a speed of up to 2800rpm to provide sufficient hot air flow.

Technical Parameter

| Product model |

ET-R8 |

| Heating system |

NO. of heating zone |

Upper 8 hot air heating, lower 8 hot air heating |

| Length of heating zone |

3000mm |

| heating method |

Full hot air |

| Delivery system |

PCB maximum width |

450mm mesh belt, no lead rail |

| Transport direction |

left-right,right to left(option) |

| Conveyor belt height |

Mesh belt 880±20mm |

| Delivery method |

Mesh belt drive + rail (optional) |

| Conveyor speed |

0-2000mm/min |

|

Control System

|

power |

380V 50/60Hz Three-phase five-wire AC:380V 50Hz |

| Starting power |

28KW |

| Working power |

7KW |

| Heating time |

Around 15 mins |

| Temperature control range |

Room temperature~350℃ |

| Temperature control method |

PID control + SSR drive |

| Temperature control accuracy |

±1℃ |

| Abnormal alarm |

Abnormal temperature alarm |

| Machine system |

Machine dimensions(L*W*H) |

5000mm*1000mm*1500mm |

| Machine weight |

1200kg |

SMT Line solution

A whole semi automatic line which needs several devices for a whole semi production, as semi auto stencil printer machine, conveyor, pick and place machine and reflow oven etc.

Packages

Step 1: Wrap with stretch film to prevent the equipment from.

Step 2: Vacuum paper packaging and moisture-proof bag, so that the machine can be kept dry during transportation to prevent moisture.

Step 3: Use straps and triangular wood to fix the machine to prevent damage to the machine during transportation.

Step 4: Each exported machine will be equipped with sturdy export wooden boxes, to ensure that the delivered product is good.

Service

Pre-sale service

Provide suitable production plan

Advise on plant electrical equipment and layout

Sale service

Report machine status in time

Follow up and send test machine video

After-sales service

Software lifetime upgrade

24 hours to deal with problems online

Engineers can arrive on site to teach operation and debug the machine

Regular visit (one year warranty period, spare parts repair free; Once or twice a year after warranty)

FAQ

Q. Does your machines have quality certificates?

A. We are high-tech enterprise with CE, SIRA, CCC , ISO awarded as "Well-know brand" and many technology patents, and have rich experience (more than 11 years) in LED light production line program.

Q. Can I use CIF price?

A. CIF price need add the freight and insurance fee, while for the part of EXW which is cheaper and convenient factor as a suitable price for both sides.

Q. What is your machines quality?

A. As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 112 practical patents, 12 software copyrights, with our won R&D department for production and inspection. And awarded as “China high-tech enterprise”, “Shenzhen TOP brand” we ensure our high quality of our machine as an excellent manufacturer in China.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!