Best condition 500000k capacity SMT roll to roll placement machine

Machine main features

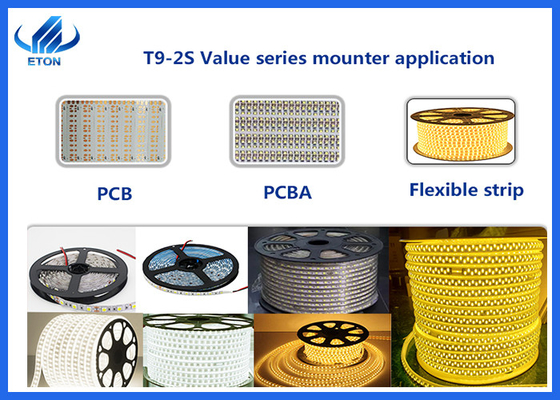

- Wide components range: High speed modular heads apply to LED 3014/3020/2835/5050 and resistors, capacitors, bridge rectifiers etc.

- Unique design component leaking detection and individual component refill function. Recognition camera record the component leaking position of PCB, and fill the missing component accordingly.

- Ultra high speed capacity: 500,000 CPH

- Intelligent electric feeder,supporting high-speed machine series.

- Adjust the conveying platform according to various roll to roll strip, range 250±10 mm, the max length range is 1M per cycle.

- The distance of feeder station can be flexibly adjusted to achieve group picking and group placing, so as to realize the function of two time picking and once placing.

- The range of feeder station is double of placement four kinds of materials at the same time.

- Automatic production with identification date, correction and fill missing component automatically.

- Flight recognition camera, no pause to detect the presence or absence of components, component adsorption state, prevent placement errors.

- The clamping rod is driven by the air cylinder to correct the materials taken by mounting head.

- With the function of filling missing component automatically, realize industry 4.0 Unmanned Workshop.

- Complaint with CE standards.

Machine main parameter

| Model |

T9-2S |

| Dimension |

(L)3454*(W)3035*(H)1777 mm |

| Total weight |

3100 kg |

| PCB size |

250(±10)mm* Any length |

| PCB thickness |

0.1-0.5 mm |

| PCB clamping |

Vacuum adsorption, cylinder clamping, track width adjustable |

| Mounting way |

Group picking and group placing |

| Mounting mode |

Double rail + Four groups of placement heads |

| No. of camera |

10 sets (Digital camera) |

| Software |

R&D independently |

| Repeat precision |

±0.05 mm |

| Mounting height |

≦5 mm |

| Mounting speed |

Double side: 500,000 CPH

Single side: 250,000 CPH (Optimum speed)

|

| Components range |

LED 3014/3020/2835/5050 and resistors, capacitors, bridge rectifiers etc. |

| Power consumption |

9.6 KW |

| No. of feeder station |

Double side: 136 PCS (Single side: 68 PCS) |

| No. of nozzles |

Double side: 136 PCS (Single side: 68 PCS) |

Machine main part

Market

Our products had exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc. And here are some of our big customers:

SURYA, POLYCAB, FIEM, RK, GK, TECHNO LED, CALCOM, ACK , KENDAL, RangDong, UNISTAR, and so on.

Packages

Our package step is follow the blowing:

STEP 1: Film packaging to prevent the dust and water;

STEP 2: Packing in a foam cotton stretch a film to protect the outside of the machine;

STEP 3: Vacuum paper package and moisture proof bag, to keep dry during the transportation;

STEP 4: Equip with sturdy wooden boxes to ensure the safety of the machine, then transportation by trucks to the specified port.

Delivery: by sea, air, land transport.

FAQ

Q. How is the differences of your multifunctional machine and high-speed machine?

A. The mounting mode of multifunctional and high speed machine which decides the range of their mounting products, and the mounting capacity is to distinguish this two types of the machine, such as multifunctional pick and place machine KT10S with capacity of 48000 CPH, while high sr machine T9-2S with 500000 CPH capacity.

Q.How can I make inspection when something wrong with the machine?

A. Well, the inspection is taken by our professional engineer to check and modulate the machine, if you counter any problem of our machine please contact us, and we will arrange our engineer to solve it.

Q. How long is the machine maintenance period, whether it is free?

A. The maintenance period of our machine is 1 year and its free for our clients, after the maintenance period we will arrange our engineers to check and test the machine one or two times a year freely.peed mounte

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!