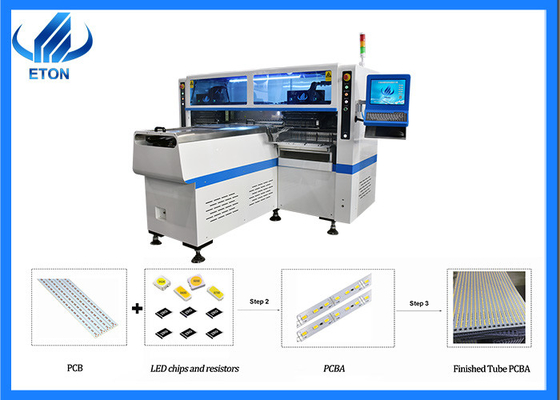

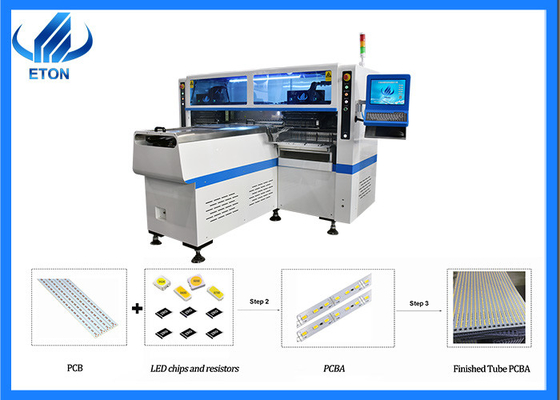

High efficiency Full-automatic 250000 CPH pick and place machine for Led tube/strip /panel lamp

The function of highspeed led mounting machine

The function of led chip mounter machine is mounting the components(led chip/ resistor/ capacitor/ ic/ shaped components etc) on the PCB. The led chip mounter machine is the main equipment in the SMT line, and also it influence whole SMT line capacity.

Machine parameter

| Model |

HT-F9 |

| Dimension(L*W*H) |

2700*2300*1550mm |

| Weight |

1700kg |

| PCB length width |

Max:1200*330mm;Min:100*100mm |

| PCB thickness |

0.5~5mm |

| Mounting precision |

±0.02mm |

| Mounting mode |

Group to take and group to mount |

| Mounting height |

≤5mm |

| Mounting speed |

250000 CPH |

| Power consumption |

6KW |

| No. Of feeders station |

68 PCS |

| No. Of head |

68 PCS |

Company information

1: China’s No. 1 SMT high speed pick and place machine manufacturer

2: Focusing on SMT pick and place machine more than 11years

3: The products exported to more than 20 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc.

4: ETON obtained 9 invention patents, 112 practical patents, 12 software copyrights of intellectual property technologies, to be a leading manufacturer of SMT trade.

INDUSTRIAL PARK

We have our own industrial park,equipped with and advanced processing and manufacturing center,strict quality control,and standardize production,streamline production processes.and there is the fastest machine in the world,the capacity reach 50W CPH.

Shipping and Delivery

Shipping Way:

※ By air, for sample and small package

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 30 Days.

Related machine

We can provide you a whole SMT line solution and equipment, you can look this picture, we have semi-auto/full-automatic stencil printer, glue dispenser(this machine is mainly for making led lens), conveyor, reflow oven, etc.

We can meet your any demands for equipment, and pursue quality higher than price for machine manufacturing

Precautions for reflow soldering

1. In order to ensure personal safety, the operator must take off the label and decorations, the sleeves can not be too loose.

2. Operation should pay attention to high temperature, avoid scald maintenance.

3. Do not set the temperature zone and speed of reflow soldering.

4. Make sure the room is well ventilated and that the chimney leads out of the window.

Service

We have professional sales staff for you to introduce the machine details, and provide you with real information; Can be customized according to the production needs of customers; We have overseas engineers who can install, train and debug machines at home, all free of charge; We have Chinese engineers to operate the equipment remotely and provide teaching videos. In addition, we will regularly return visits, real-time understanding of the customer's production status.

Smt production line configuration (three core production equipment)

The general smt production process includes three steps of solder paste printing, pick and place machine and reflow soldering. The placement machine is the primary core equipment: it is used to achieve high-speed, high-precision, fully automatic placement of components, which is related to the efficiency and accuracy of the SMT production line, and is the most critical and complex equipment. In many equipment, the placement machine often accounts for more than 70% of the investment of the entire production line, so the selection of the placement machine is very important.

FAQ

What kind of led lighting your machine suitable using for?

A: Our machine widely applied to all kinds of led lighting and driver board. Besides, our machine function is mounting SMD components on the PCB.

What is the lead time of your machine?

A: The lead time of our machine need around 7 days ---20 days. Different module will required different time.

What is your machine certificates?

A:Our machine supply CE/CCC/SIRA certificates.

Contact David

Whatsapp/Wechat: +86 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!