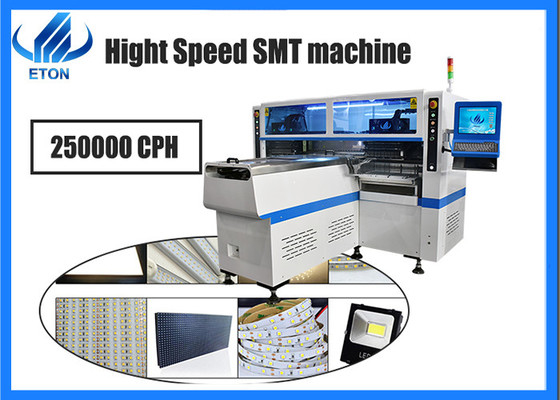

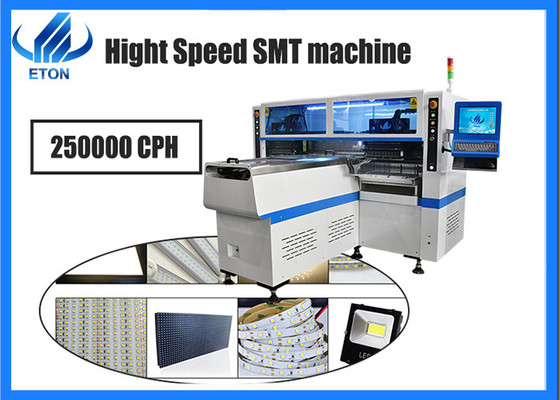

High efficiency Full-automatic 250000 CPH pick and place machine for Led tube/strip /panel lamp

The function of highspeed led mounting machine

The function of led chip mounter machine is mounting the components(led chip/ resistor/ capacitor/ ic/ shaped components etc) on the PCB. The led chip mounter machine is the main equipment in the SMT line, and also it influence whole SMT line capacity.

Machine parameter

| Model |

HT-F9 |

| Dimension(L*W*H) |

2700*2300*1550mm |

| Weight |

1700kg |

| PCB length width |

Max:1200*330mm;Min:100*100mm |

| PCB thickness |

0.5~5mm |

| Mounting precision |

±0.02mm |

| Mounting mode |

Group to take and group to mount |

| Mounting height |

≤5mm |

| Mounting speed |

250000 CPH |

| Power consumption |

6KW |

| No. Of feeders station |

68 PCS |

| No. Of head |

68 PCS |

SMT production line

SMT line solution for our clients as a professional SMT manufacturer which is an indispensable task to show a qualified service to our customers, here are the four main types of machine:

1.Solder printer machine: The function of the machine is to leave the solder paste on the PCB

2.Pick and place machine: It is to mount led chips or other surface mounted components at the designated position of PCB board;

3.Conveyor: It is used for the connection between SMT production lines, as well as buffering, testing, testing PCB boards or manual plug-in of electronic components;

4.Reflow oven: It is to melt the solder paste to fix and bond the components and PCB board.

Company information

1. SMT equipment: Pick and place machine/reflow oven/stencil printer/pcb conveyor/SPI/AOI.etc

2. Light Factory for :led bulbs,DOB,lens,panel light,downlight,streetlight,tube,0.5m,1m strip light,etc.

3. Provide Overseas engineers for Free installation and free training.

4. TOP brand of China SMT machine manufacturer,500 employees for ETON

5. Oversea market:The products exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc.

We can provide SMT line solution and better serivce for you!

INDUSTRIAL PARK

We have our own industrial park,equipped with and advanced processing and manufacturing center,strict quality control,and standardize production,streamline production processes.and there is the fastest machine in the world,the capacity reach 50W CPH.

Shipping and Delivery

Land transportation: suitable for inland countries and it is affordable;

Air freight: for urgent good, and it is the most expensive transportation way;

Shipping: It’s suitable for heavy goods, and the convenience and lower cost of shipping which is easy for clients to accept the arrival time of the goods.

Related machine

We can provide you a whole SMT line solution and equipment, you can look this picture, we have semi-auto/full-automatic stencil printer, glue dispenser(this machine is mainly for making led lens), conveyor, reflow oven, etc.

We can meet your any demands for equipment, and pursue quality higher than price for machine manufacturing

Service

※ Maintenance period 1year

One year warranty, during warranty, any parts need to be repaired and replaced will be free.

※ Software and hardware lifetime maintenance

Free upgrade software, software is Reach and develop by ETON, so we support whole lifetime free upgrade updates.

※ Visit customers regularly and gather information

Visit clients regularly. We attend different exhibition in different cities every year, at the same time, we will visit local clients and support our service and collect and feedback customer suggestions in time.

※ Provide latest information about technology and equipment

We give professional technology suggestion with our clients.And share the updates news to our clients

Smt production line configuration (three core production equipment)

The general smt production process includes three steps of solder paste printing, pick and place machine and reflow soldering. The placement machine is the primary core equipment: it is used to achieve high-speed, high-precision, fully automatic placement of components, which is related to the efficiency and accuracy of the SMT production line, and is the most critical and complex equipment. In many equipment, the placement machine often accounts for more than 70% of the investment of the entire production line, so the selection of the placement machine is very important.

FAQ

1. What’s the terms of payment?

T/T is OK. You can choose FOB Shenzhen.

2. Why you choose ETON?

ETON has more than 11 years experience. ETON is in the leading position in the field of pick and place machine and commit to continuously providing the market with products and services that are “ more intelligent, more professional, more efficient, and lower consumption”.

3. Who are your main clients?

Our production have exported to more than 20 countries and regions, including South Korea, India, Egypt, Turkey, Russia etc.

4. Why choose us?

ETON is the famous brand for high-end pick and place machine. We have more than 10 years experience and professional R&D team, providing 24 hours quick response after-sales service.

5. What about the package of the machine?

We use wooden boxes and vacuum packaging to ensure that the machine is in good condition.

Contact David

Whatsapp/Wechat: +86 13827425982

E-mail: david@eton-mounter.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!