Product Description:

The SMT Mounting Machine is a cutting-edge technology product designed for high-precision placement of surface mount components in various electronic devices. This advanced equipment falls under the Product Category of SMT Mounting Machine, specifically catering to the needs of industries requiring precise and efficient component mounting.

Equipped with a remarkable number of nozzles, the SMT Mounting Machine offers exceptional productivity and versatility. It features Double side with 136 PCS of nozzles and Single side with 68 PCS of nozzles, enabling it to handle a wide range of components with speed and accuracy. Whether you are working on complex circuit boards or delicate flexible strip lights, this machine can efficiently handle the task at hand.

Enhancing its precision capabilities, the SMT Mounting Machine boasts 10 sets of Digital cameras, providing comprehensive visual inspection and guidance during the mounting process. This advanced camera system ensures precise component placement, contributing to flawless assembly and optimal performance of electronic devices.

When it comes to mounting height, the SMT Mounting Machine offers a maximum mounting height of ≦5 mm, allowing for the accurate placement of components within tight tolerances. This feature is crucial for ensuring the reliability and functionality of electronic devices, especially those with compact designs and intricate layouts.

In terms of power consumption, the SMT Mounting Machine is designed for efficiency and sustainability. With a power consumption of 9.6 KW, this equipment delivers high performance while maintaining energy efficiency, making it a cost-effective solution for businesses seeking to reduce their operational costs.

Overall, the SMT Mounting Machine is a state-of-the-art SMD Pick and Place Equipment that excels in precision, speed, and reliability. Whether you are manufacturing consumer electronics, automotive components, or industrial machinery, this Surface Mount Component Mounter is a valuable asset that enhances production efficiency and product quality.

Features:

- Product Name: SMT Mounting Machine

- PCB thickness: 0.1-0.5 mm

- Dimension: (L)3454*(W)3035*(H)1777 mm

- No. of feeder station: Double side: 136 PCS, Single side: 68 PCS

- Product Category: SMT Mounting Machine

- Components range: LED 3014/3020/2835/5050 and resistors, capacitors, bridge rectifiers etc.

Technical Parameters:

| Power consumption |

9.6 KW |

| PCB size |

250(±10)mm* Any length |

| Product Category |

SMT Mounting Machine |

| No. of camera |

10 sets (Digital camera) |

| Dimension |

(L)3454*(W)3035*(H)1777 mm |

| Mounting mode |

Double rail + Four groups of placement heads |

| Product Name |

Super high speed roll to roll led flexible strip light SMT |

| No. of nozzles |

Double side: 136 PCS, Single side: 68 PCS |

| Mounting speed |

Double side: 500,000 CPH, Single side: 250,000 CPH (Optimum speed) |

| PCB thickness |

0.1-0.5 mm |

Applications:

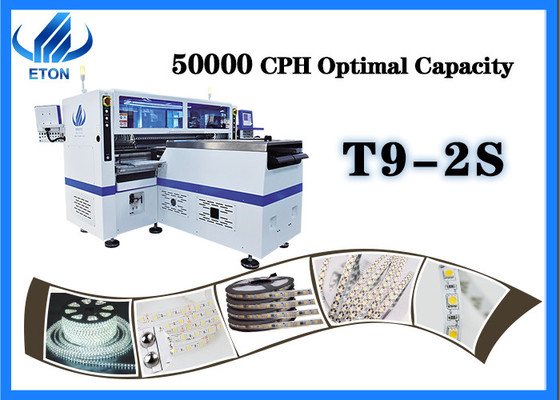

Eton's T9-2S SMT Mounting Machine is a versatile and efficient solution for a wide range of product application occasions and scenarios. With its advanced features and capabilities, this machine is ideal for various industries and businesses looking to streamline their production processes.

One of the key product application occasions for the T9-2S is in the manufacture of LED light rolls. The machine's precise mounting capabilities make it perfect for accurately placing SMD components onto flexible substrates, ensuring high-quality and reliable LED light rolls production.

Another important scenario for the Eton SMT Mounting Machine is in the production of Mounting Devices for SMD Components. The machine's vacuum adsorption and cylinder clamping mounting way allow for secure and accurate placement of components, making it an essential tool for manufacturing SMD component mounting devices.

Additionally, the T9-2S is well-suited for the production of LED flexible strips. Its track width adjustable mounting way and mounting height of ≤5 mm enable the machine to handle the delicate and precise mounting requirements of LED flexible strips, ensuring consistent quality and performance.

With certifications including CE, SIRA, CCC, and ISO, customers can trust in the quality and reliability of the Eton SMT Mounting Machine. Originating from Shenzhen, China, the machine is built to meet international standards and specifications, making it a preferred choice for businesses worldwide.

Available for a minimum order quantity of 1 unit and priced between USD10000 to USD43000 per unit, the T9-2S offers excellent value for its capabilities. Customers can choose from a variety of payment terms including T/T, L/C, Western Union, MoneyGram, and D/P, making it convenient to acquire this high-performance machine.

With a supply ability of 30 units per month and a delivery time within 15 days after receiving the downpayment, customers can rely on the Eton SMT Mounting Machine to meet their production needs efficiently. The machine comes packaged in a standard export wooden case package, with the flexibility to accommodate customers' specific packaging requirements.

Weighing 3100 kg and consuming 9.6 KW of power, the T9-2S is a robust and energy-efficient solution for SMT mounting applications. Its advanced features, precision mounting capabilities, and reliable performance make it a valuable asset for businesses operating in industries such as LED light roll manufacturing, SMD component mounting device production, and LED flexible strip fabrication.

Support and Services:

Our SMT Mounting Machine product comes with comprehensive Product Technical Support and Services to ensure optimal performance and customer satisfaction. Our technical support team is available to assist with any inquiries, troubleshooting, or maintenance needs related to the machine. Additionally, we offer training programs, installation services, and ongoing maintenance contracts to keep the machine operating at peak efficiency. Our goal is to provide reliable and efficient support to maximize the value and longevity of your SMT Mounting Machine investment.

Packing and Shipping:

Product Packaging:

The SMT Mounting Machine is carefully packaged in a sturdy cardboard box with ample cushioning to ensure safe transportation.

Shipping:

We offer worldwide shipping for the SMT Mounting Machine. Orders are typically processed within 1-2 business days and shipped via trusted carriers to ensure timely delivery to our customers.

FAQ:

A: The brand name is ETON.

Q: What is the model number of the SMT Mounting Machine?

A: The model number is T9-2S.

Q: Where is the SMT Mounting Machine manufactured?

A: The SMT Mounting Machine is manufactured in Shenzhen, China.

Q: What are the accepted payment terms for purchasing the SMT Mounting Machine?

A: The accepted payment terms are T/T, L/C, Western Union, MoneyGram, and D/P.

Q: What is the delivery time for the SMT Mounting Machine?

A: The delivery time is within 15 days after receiving the downpayment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!