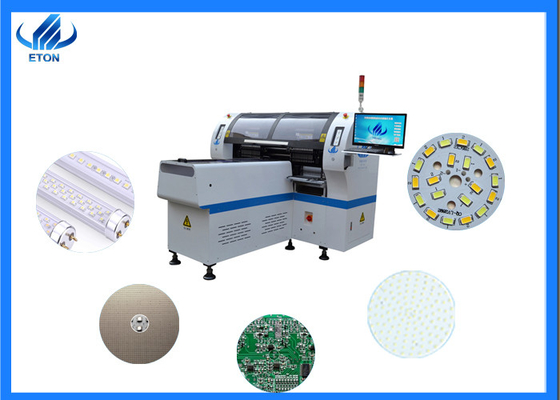

Good Stability visual system smart feeder led lights for sewing machine

HT-XF is a special machine for mounting hard and soft strips,mounting components about LED 3014/3020/3528/5050 and resistors,capacitors ,bridge rectifiers.Dual purpose professional high speed mounter ,the capacity reach 170000CPH. 17 nozzles for each mounting module part A or B can be mounted separately or synchronously.

Performance introduction

High Speed and High Precision

This special Mounter has a speed of 150000~170000 CPH.Can save space, labor costs, management costs

No. Of feeder station:34PCS nozzles:34PCS

Good durability

Using High Stability Electronic Dual Motor

The wear resistance of screw rod is not easy to deviate and has high accuracy.

The guide rail has strong bearing capacity and high stability.

High-quality hardware configuration for 24-hour machine operation.

| HT-XF |

| PCB |

PCB length width |

Max:330*1200mm min:90*330mm |

| PCB thickness |

0.5~5mm |

| PCB clamping |

Adjustable pressure pneumatic |

| Mounting mode |

Group to take and group to mount |

| O.S. |

system |

Windows 7 |

| software |

R&D independently |

| display |

LED monitor |

| Input device |

Keyboard , mouse |

|

Vision

system

|

No.of camera |

5 sets of imported camera

Vision alignment,mark correction

|

| Mounting precision |

0.02mm(repeat precision) |

| Mounting height |

<15mm |

| Mounting speed |

150000~170000CPH |

| Components |

LED 3014/3020/3528/5050 and resistors,capacitors ,bridge rectifiers. |

| Components space |

0.2mm |

| No.of feeders station |

34PCS |

| No.of nozzles |

34PCS |

| Power |

220AC 50HZ |

| Power consumption |

5KW |

| Conveyor transmission |

Max length:1200mm |

| Transmission speed |

>500mm/sec |

| Transmission direction |

Single (left to right or right or left) |

| Transmission mode |

Auto online drive |

| Position mode |

Optical |

| Air pressure |

>5.0kg /cm² |

| Electrical control |

Independent research and development by ETON |

| Motion control card module 1set |

Independent research and development by ETON |

| X,Y,X axis drive way |

Servo motor control for X,Y,Z axis |

| Feeding way |

Electric feeder with double motor |

| packing |

| 1.Filming packing |

Make the machine sanitary, clean, sealed packaging, dust and humidity; have good shock resistance, impact resistance, and good protection performance with tightness and fixity. |

| 2.vacuum packing |

Advantages of moistureproof, dustproof and so on |

| 3.wooden packing |

It has good cushioning performance, corrosion resistance, high strength and hygroscopicity, moisture-proof and earthquake-resistant functions. |

FAQ:

1,What’s the terms of payment? What about the trade term?

T/T is OK. You can choose FOB Shenzhen.

2,What is the maximum height of components that can be mounted on a machine?

The height of the mounting component can reach 36 mm, and the minimum mounting component can be 0402.

3,What is the length of the playable PCB?

Max:330*1200mm min:90*120mm

4,Is this machine difficult to operate?

No, not at all. For our previous clients, at most 5 days is enough to learn to operate the machines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!