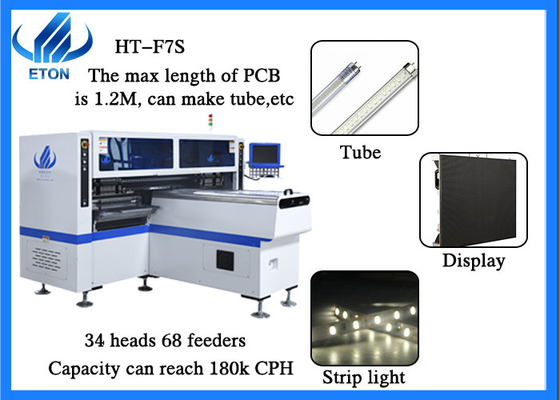

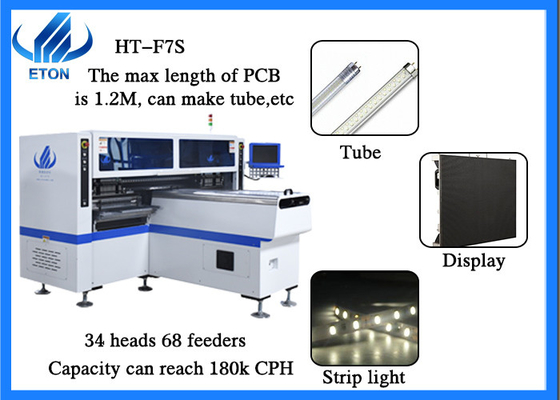

18000CPH tube display making machine 34 heads 68 feeders SMT pick and place machine

Product description

| 1. In the design of this model, in order to improve the production capacity, 34 suction nozzles and 68 feeders seats are designed. The mechanical arms of the two groups of suction elements move on the same track, making its maximum production capacity exceed 180000 CPH. |

|

2. A plate of materials can be pasted separately, or 2-4 kinds of raw materials can be pasted at the same time, and the ingredients can be programmed according to the customer's PCB design.

|

|

3. The application software of mounter is independently developed by ETON. It is not only easy to learn, but also can be updated free of charge and guaranteed for life

|

PCB board

1. The PCB board can be 1.2m to the longest and the width is 330mm, which means that it can be installed on large application products, long tube, large panel lamp and so on.

2. Take it together and stick it together. This technology speeds up the mounting speed to a certain extent, but you can rest assured that the speed is accelerated and the accuracy is guaranteed.

Features

| 1. With automatic correction function, there is no need for manual continuous monitoring, and RGB can also be pasted. |

|

2. The position of mounting components is designed on the PCB board. There is no need to wait under any proportion of lamp beads and resistors to realize one-time mounting.

|

|

3. Five cameras monitor each other to ensure that mark is programmed and pasted correctly.

|

Parameter

| PCB thickness |

0.5-5mm |

| PCB clamping |

Adjustable pressure pneumatic |

| No.of camera |

5 PCS |

| Repeating precision |

±0.02mm |

| Power consumption |

6KW |

| Power |

380AC50Hz |

| Mounting speed |

150000CPH - 180000CPH |

| Components space |

0.5mm |

Specific operation steps of SMT Mounter wire change

When the SMT Mounter completes the current production plan and converts to another mounting plan, it needs to change the line to mount another product. We should reprogram all the data of the mounter in time, replace the feeder, adjust the substrate transportation organization and positioning table, and adjust and replace the mounting head to replace the line.

1. Reprogram the mounter system: Mounter system generally adopts manual programming and computer programming. The low-end Mounter usually adopts manual teaching programming, while the high-end Mounter can adopt computer active programming.

2. Replace the feeder of the original chip product: In order to reduce the moment when the feeder of the mounter is replaced, the common method is to use the "quick unloading" feeder, and the faster method is to replace the feeder structure, so that the feeder of each component on the substrate type of the mounter is installed on a separate feeder frame for replacement.

3. Adjust the transmission mechanism and positioning table of the mounter: When the size of the replaced substrate is different from that of the current device, adjust the width of the substrate positioning table and the conveying mechanism for conveying the substrate. The mounter can be adjusted actively under program control, and the next level Mounter can be adjusted manually.

4.Replace the mounting head of the mounter: When the type of components to be installed on the substrate exceeds the equipment scale of the mounting head, perhaps when the substrate type changes, the mounting head of the mounting machine is often replaced or adjusted. Most mounters can actively replace and adjust the mounting head under program control, while some mounters need to perform such operations manually.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!